Keeping production on track requires a clear, consistent, and easily digestible flow of information. Without a structured way to communicate progress, teams can quickly become misaligned, leading to missed deadlines, budget overruns, and frustrated stakeholders. This is where a well-designed Production Status Report Template becomes an indispensable tool for any manager or team lead. It provides a standardized framework for capturing vital data, highlighting achievements, and flagging potential roadblocks before they escalate into full-blown crises. By moving away from ad-hoc emails and scattered updates, you create a single source of truth that keeps everyone, from the factory floor to the executive suite, perfectly in sync.

The chaos of an unmanaged production process is a familiar pain point for many organizations. Team members spend valuable time trying to figure out what information to include in their updates, while managers waste hours collating disparate reports into a coherent overview. This lack of standardization often leads to critical details being missed. One report might focus heavily on output numbers but omit resource constraints, while another might detail a potential risk without outlining a mitigation plan. The result is a murky, incomplete picture of the production landscape, making it nearly impossible to make informed, proactive decisions.

Implementing a standardized template fundamentally changes this dynamic. It establishes a clear communication protocol, ensuring that all essential information is captured and presented consistently every single time. This uniformity not only saves time for the person creating the report but also for those reading it. Stakeholders know exactly where to look for the information they need, whether it’s the overall project health, specific KPI trends, or a list of urgent action items. This efficiency frees up mental bandwidth, allowing teams to focus less on the logistics of reporting and more on the strategic work of production itself.

This article will serve as a comprehensive guide to understanding, creating, and utilizing production status reports. We will delve into the core components that make a report effective, explore the significant benefits of standardization, and provide a step-by-step process for building a template tailored to your specific needs. Furthermore, we will look at different types of templates for various production environments and share best practices to ensure your reports are not just documents, but powerful drivers of success and continuous improvement.

What is a Production Status Report?

A production status report is a formal communication tool that provides a concise, regular update on the progress of a manufacturing, development, or creative production process. Its primary purpose is to offer a snapshot in time, detailing what has been accomplished, what tasks are currently underway, and what is planned for the near future. It serves as a vital link between the production team, management, and other key stakeholders, ensuring everyone has a shared understanding of the project’s health and trajectory.

At its core, the report is an instrument of transparency and accountability. It quantifies progress using key metrics and qualitative assessments, moving beyond anecdotal updates to provide data-backed insights. For a production manager, it’s a tool for monitoring performance against established goals and timelines. For an executive, it’s a high-level summary that helps in strategic decision-making and resource allocation. For the team members themselves, it provides context for their work, clarifies priorities, and celebrates achievements, fostering a sense of shared purpose.

The scope of a production status report can vary widely depending on the industry and the reporting cadence. A daily report from a manufacturing floor might focus on shift output, equipment downtime, and quality control issues. A weekly report for a software development sprint might highlight completed user stories, velocity, and blockers impeding progress. Regardless of the specifics, all effective production reports answer the same fundamental questions: Where are we? Where are we supposed to be? What is preventing us from closing the gap?

Why is a Standardized Production Status Report Template Crucial?

While ad-hoc reporting can work for very small teams, it quickly breaks down as complexity and scale increase. A standardized template is not about adding bureaucracy; it’s about creating a streamlined and reliable communication channel. The benefits of this standardization are profound and impact nearly every aspect of the production workflow.

Ensures Consistency and Clarity

When everyone uses the same format, the information becomes predictable and easy to digest. Stakeholders don’t have to waste time deciphering different layouts or hunting for missing data. A consistent structure means that a comparison between this week’s report and last week’s is a true apples-to-apples comparison, making it simple to spot trends, track progress over time, and identify recurring issues. This clarity eliminates ambiguity and reduces the risk of misinterpretation.

Saves Time and Boosts Efficiency

Creating a report from scratch every single time is a significant drain on resources. A template provides a ready-made structure, allowing the reporter to focus on gathering and analyzing the data rather than on formatting and presentation. This simple change can save hours each week, which can be reinvested into more productive, value-adding activities. For the readers, the efficiency gains are just as significant, as they can quickly scan the document for the information most relevant to them.

Improves Communication and Alignment

A production status report template acts as a “single source of truth.” It centralizes all critical updates into one document, ensuring that every team member, manager, and stakeholder is working from the same information. This alignment is critical for preventing miscommunication, managing expectations, and ensuring that cross-functional teams are moving in the same direction. When everyone is on the same page, collaboration becomes smoother and decision-making becomes faster.

Facilitates Proactive Problem-Solving

One of the most valuable aspects of a good template is a dedicated section for risks, issues, and blockers. By making this a mandatory part of every report, you create a culture where problems are surfaced early and openly. This proactive approach allows teams to address challenges before they derail the production schedule or impact quality. Instead of reacting to crises, the team can anticipate potential hurdles and develop mitigation strategies in advance.

Key Components of an Effective Production Status Report Template

A powerful template is more than just a blank document; it’s a structured framework designed to elicit the most important information concisely. While you should tailor your template to your specific needs, these core components are universally applicable and form the backbone of a great report.

Report Header Information

This is the basic identifying information that provides context at a glance. It should always be at the top of the report.

- Project/Product Name: The specific production line, project, or product being reported on.

- Report Date/Period: The date the report was created and the time frame it covers (e.g., “Week of October 23, 2023” or “Daily Shift: 10/24/2023, 7 AM – 3 PM”).

- Author/Manager: The name of the person or department responsible for the report.

- Overall Status: A high-level status indicator, often using a Red-Amber-Green (RAG) system: Green (On Track), Amber (At Risk), Red (Delayed/Critical Issues).

Executive Summary

This section is for senior leaders and busy stakeholders who may not have time to read the entire report. It should be a 2-4 sentence summary of the most critical information, including the overall status, one or two major accomplishments from the period, and the most significant challenge or blocker.

Key Performance Indicators (KPIs)

This is the data-driven heart of the report. The KPIs you choose should directly reflect the goals of the production process. Vague metrics are useless; be specific and quantitative.

- Manufacturing: Units Produced vs. Target, Defect Rate, Overall Equipment Effectiveness (OEE), On-Time Delivery Percentage.

- Software Development: Sprint Velocity, Burndown/Burnup Chart, Cycle Time, Number of Bugs Opened vs. Closed.

- Creative Production (e.g., Video): Scenes Shot vs. Planned, Budget Spent vs. Planned, Asset Completion Percentage.

Progress and Milestones Achieved

This section details what the team has successfully completed during the reporting period. It’s a look back at the work done. Use bullet points for clarity.

- List specific tasks, milestones, or goals that were finished.

- Compare this to what was planned for the period to show if the team is on, ahead of, or behind schedule.

- Example: “Completed assembly of 500 units (Target: 480),” or “Deployed user authentication feature to staging environment.”

Current and Upcoming Tasks

This section shifts the focus to the future, outlining the priorities for the next reporting period. This helps manage expectations and ensures resources are aligned for the work ahead.

- List the key tasks and objectives for the next week or day.

- Assign owners to each task to ensure clear accountability.

- This helps other teams anticipate dependencies on the production team’s work.

Risks, Issues, and Blockers

This is arguably the most important section for proactive management. It provides a transparent view of anything hindering progress.

- Risks: Potential problems that have not yet occurred but could impact the project (e.g., “Risk of a key supplier delaying a shipment next month”).

- Issues: Problems that are currently happening (e.g., “Machine #3 is operating at 50% capacity due to a mechanical fault”).

- Blockers: Specific obstacles preventing the team from completing a task (e.g., “Cannot proceed with testing until the marketing team provides final copy”).

Budget and Resource Utilization

For many projects, staying within budget is as important as staying on schedule. This section provides a financial and resource overview.

- Budget: Actual Spend vs. Planned Budget.

- Resources: Note any constraints or issues related to personnel (e.g., team member on unexpected leave), equipment, or materials.

How to Create and Implement Your Own Template

Building and rolling out a new template requires a thoughtful approach. Following a structured process will increase adoption and ensure the template effectively serves its purpose.

Step 1: Identify Your Audience and Goals

First, ask yourself who will be reading this report. An executive C-suite member needs a high-level summary, while a team lead needs granular details about specific tasks and blockers. The content and level of detail should be tailored to your primary audience. Simultaneously, define the primary goal of the report. Is it to track daily output, manage a complex project timeline, or communicate high-level progress to investors? Your goal will dictate the key sections and metrics.

Step 2: Define Key Metrics and Sections

Based on your audience and goals, select the components that matter most. A daily manufacturing report might prioritize KPIs like unit output and defect rates, while a creative project report might focus more on milestone completion and budget tracking. Start with the core components listed in the previous section and add, remove, or modify them to fit your unique context.

Step 3: Choose Your Format (Excel, Google Sheets, Project Management Tool)

The tool you use can have a big impact on the template’s usability.

* Spreadsheets (Excel, Google Sheets): Highly flexible, accessible, and easy to use. They are perfect for creating custom layouts and performing simple calculations. Google Sheets offers the added benefit of real-time collaboration.

* Document Editors (Word, Google Docs): Better for reports that are more narrative-heavy, but less effective for tracking quantitative data and KPIs.

* Project Management Software (Jira, Asana, Trello): Many of these tools have built-in reporting features that can automatically pull data from tasks and projects, saving significant time and reducing manual entry errors.

Step 4: Design and Build the Template

Create a clean, well-organized layout. Use clear headings, ample white space, and visual cues like color-coding for status (RAG). If using a spreadsheet, use tables and charts to visualize data, making it easier to understand trends at a glance. Ensure there are clear instructions or example text to guide users on how to fill out each section.

Step 5: Train Your Team and Standardize Usage

Don’t just email the template and expect everyone to use it correctly. Hold a brief training session to walk the team through the template, explaining the purpose of each section and the importance of consistent reporting. Set a clear schedule (e.g., “The report must be completed by 9 AM every Monday”) and make it a non-negotiable part of your team’s operating rhythm.

Step 6: Review and Iterate

A template is a living document. After a few weeks of use, gather feedback from both the creators and the readers of the report. Is any section confusing? Is there missing information that would be valuable? Are some fields redundant? Use this feedback to make continuous improvements, ensuring the template remains a valuable and efficient tool over time.

Free Downloadable Production Status Report Template Examples

Every production environment is different. A one-size-fits-all approach rarely works. Here are a few examples of specialized templates designed for common use cases.

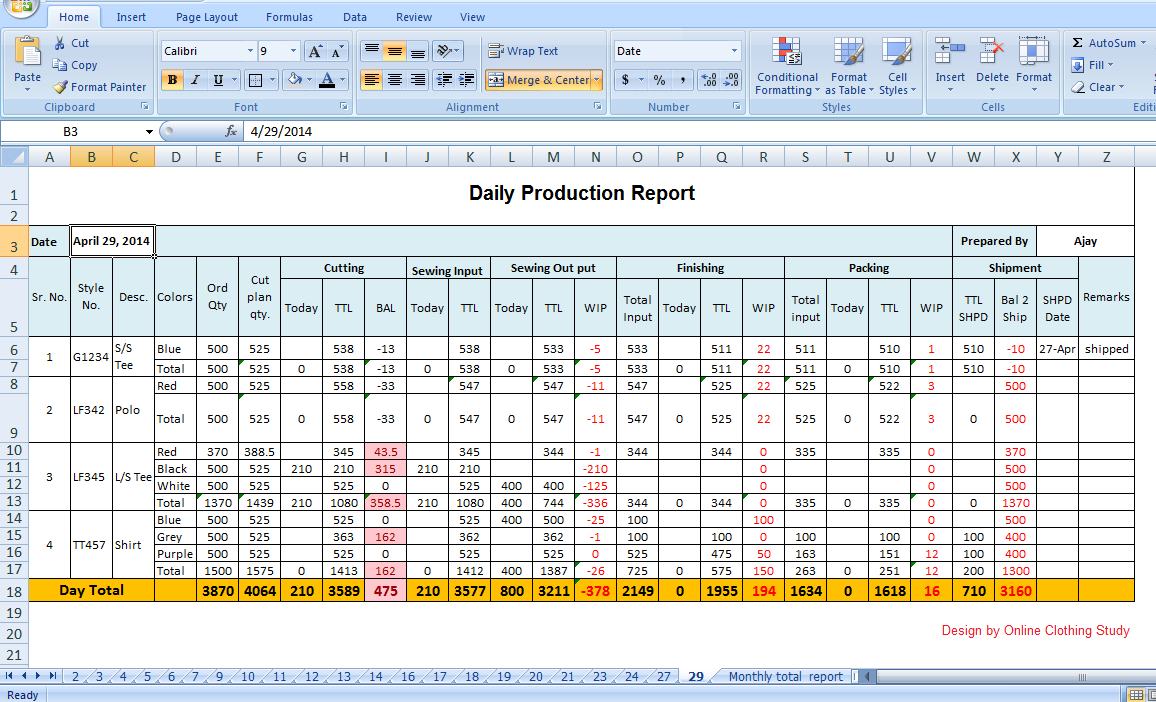

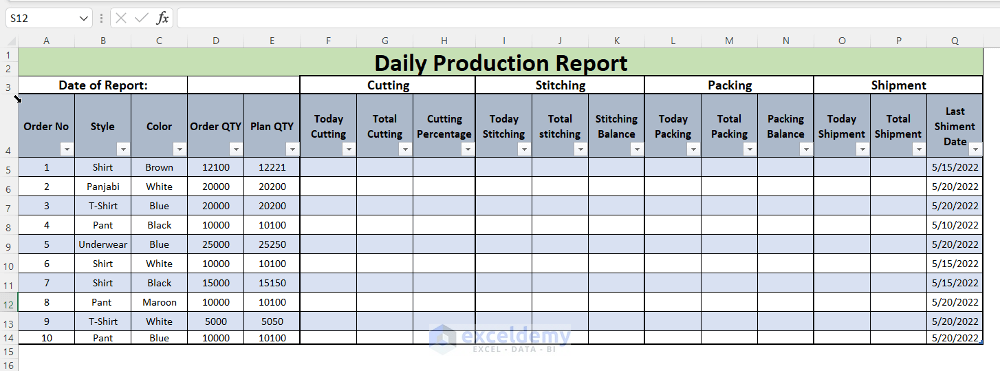

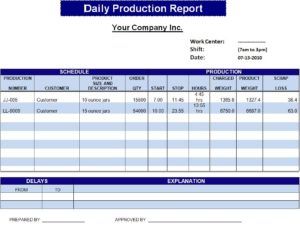

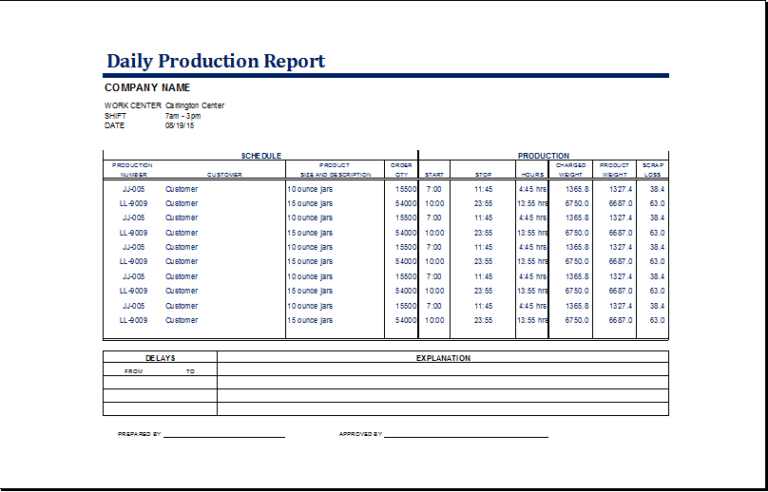

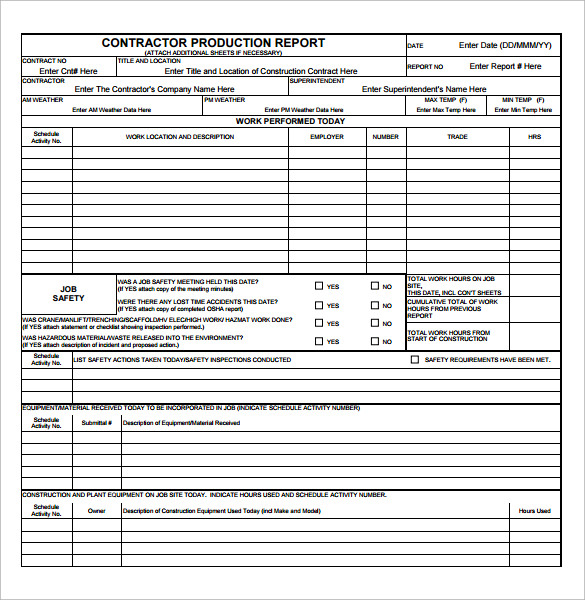

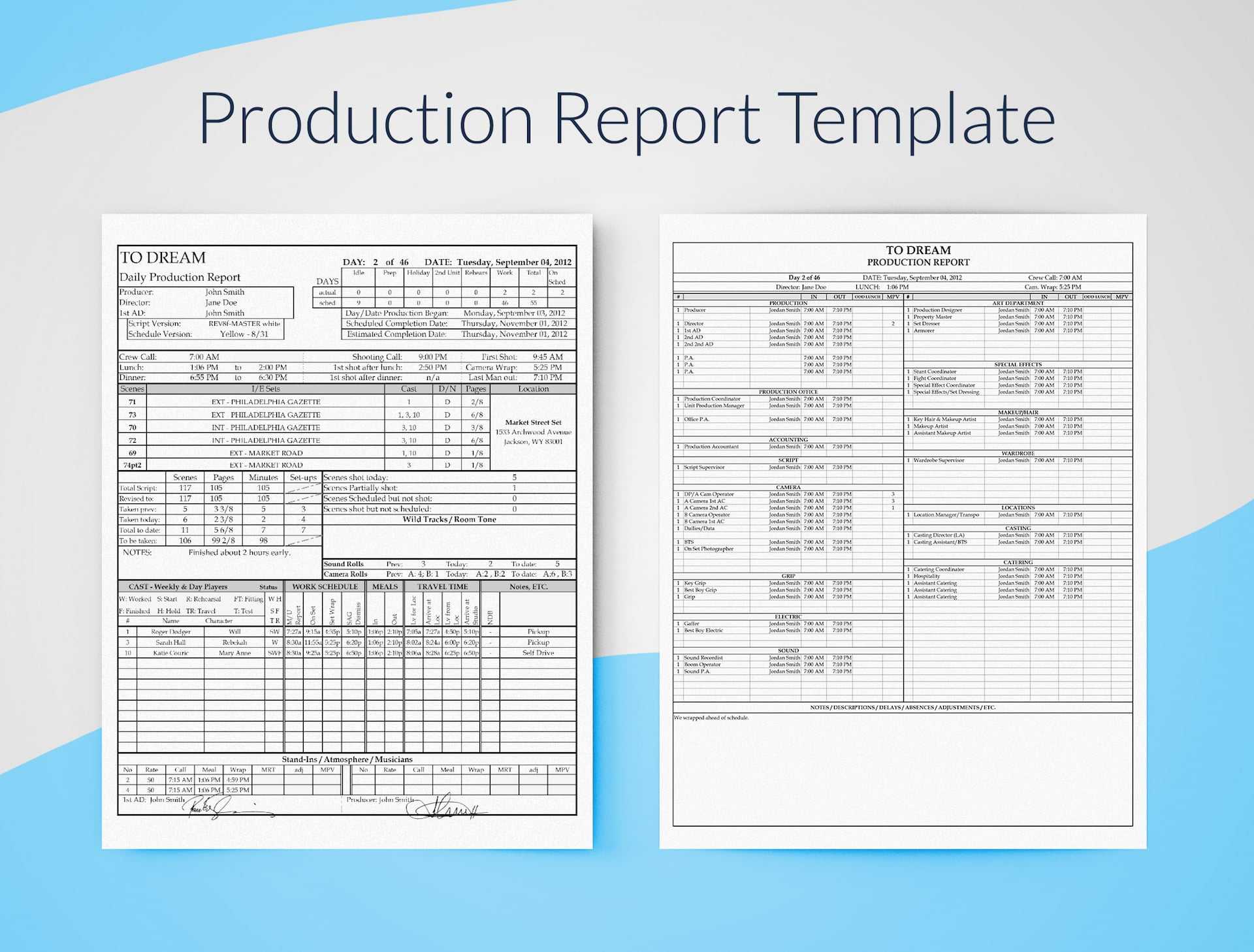

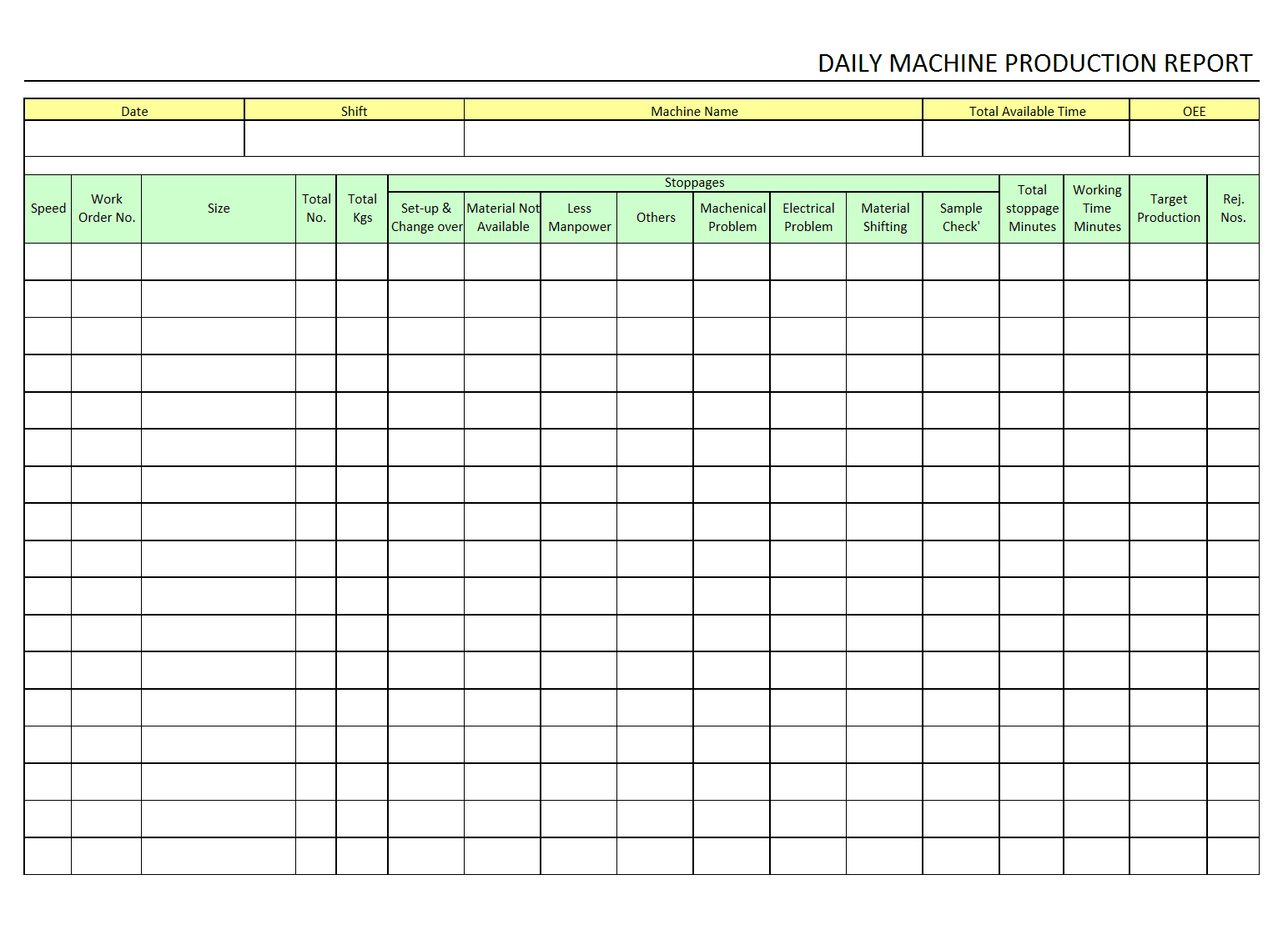

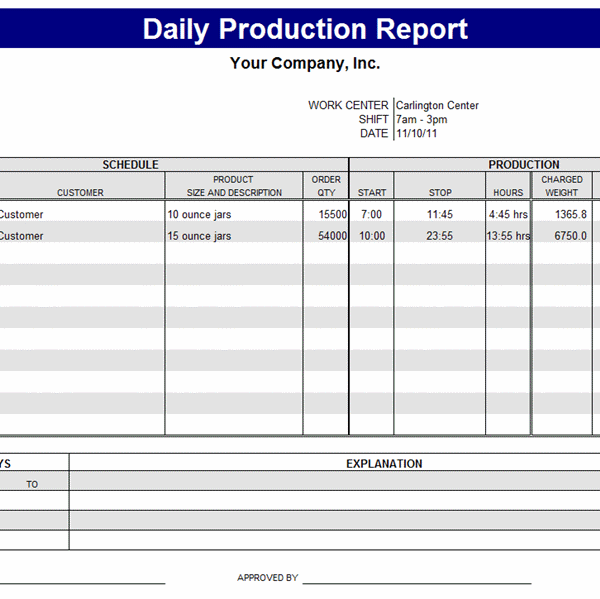

Daily Production Shift Report Template

This template is designed for high-frequency reporting in environments like manufacturing or logistics. It’s granular and focuses on the immediate operational picture.

* Key Sections: Shift Supervisor, Date/Shift Time, Production Targets vs. Actuals, Downtime Log (with reasons), Quality Control Checks, Safety Incidents, and Notes for the Next Shift.

* Purpose: To ensure a smooth handover between shifts and to track operational performance on an hourly or daily basis.

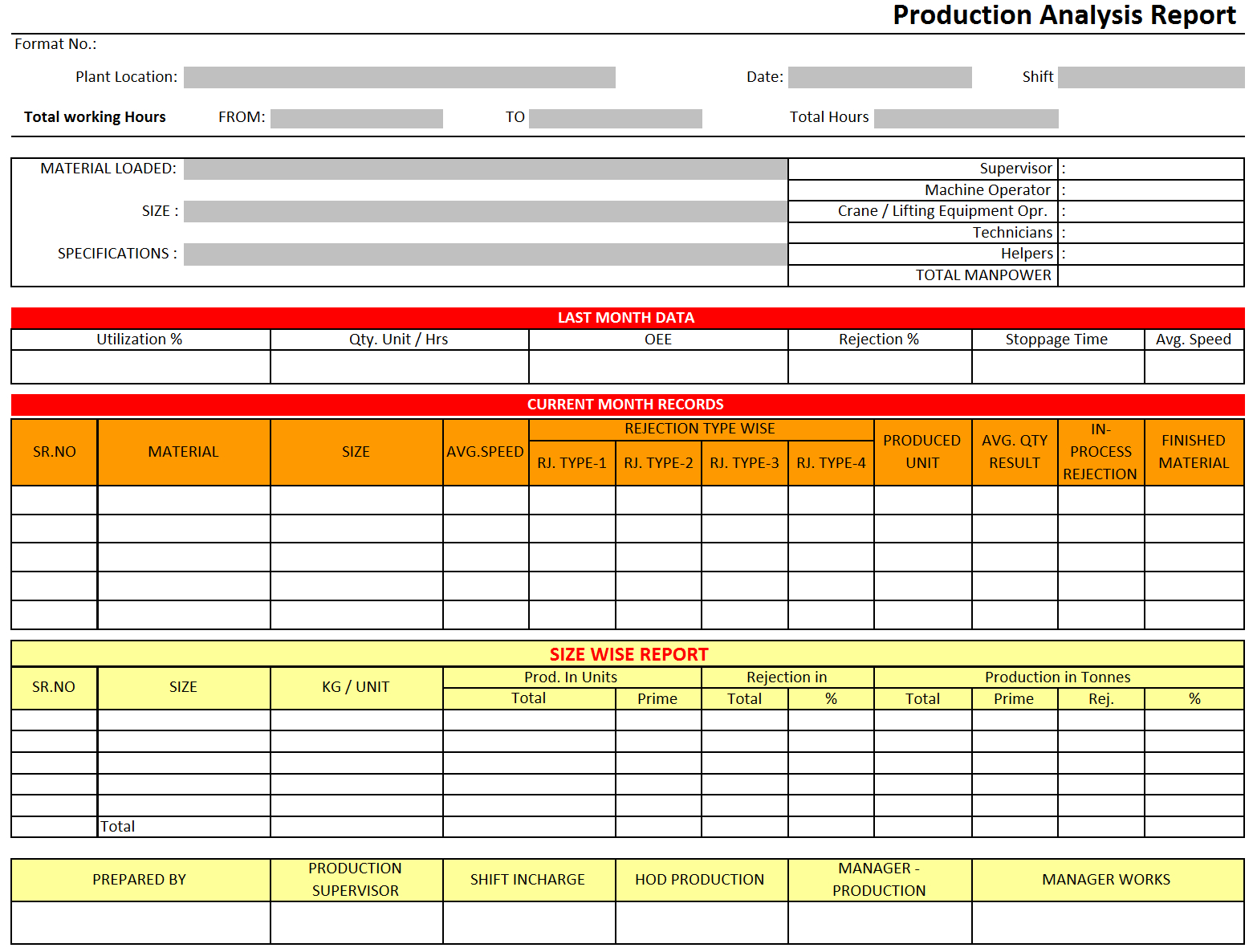

Weekly Manufacturing Production Status Report Template

This report takes a broader view than the daily shift report. It’s intended for plant managers and department heads to review weekly performance and plan for the week ahead.

* Key Sections: Executive Summary (RAG Status), Weekly KPI Dashboard (OEE, On-Time Delivery, etc.), Major Accomplishments, Production Goals for Next Week, Key Issues and Action Plans, and Inventory Levels.

* Purpose: To provide a strategic overview of the plant’s performance and to align teams on weekly priorities.

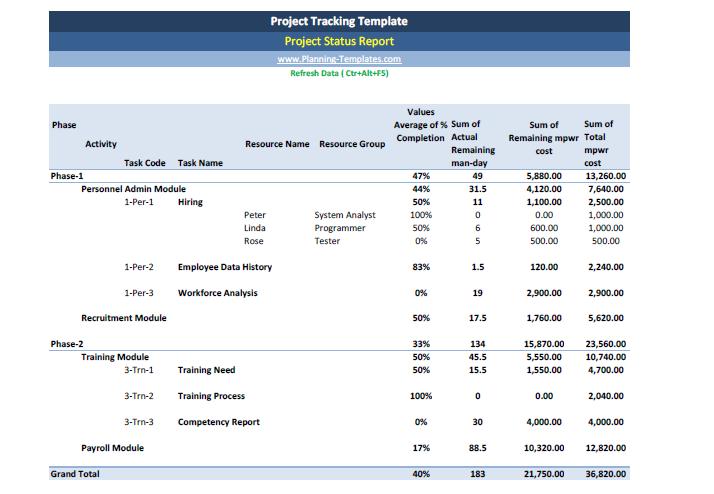

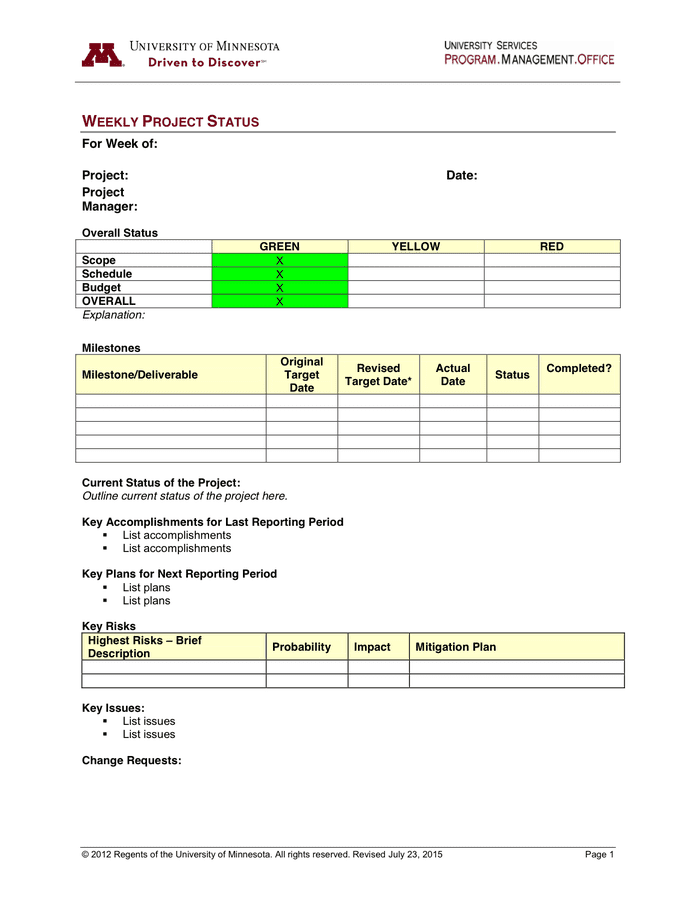

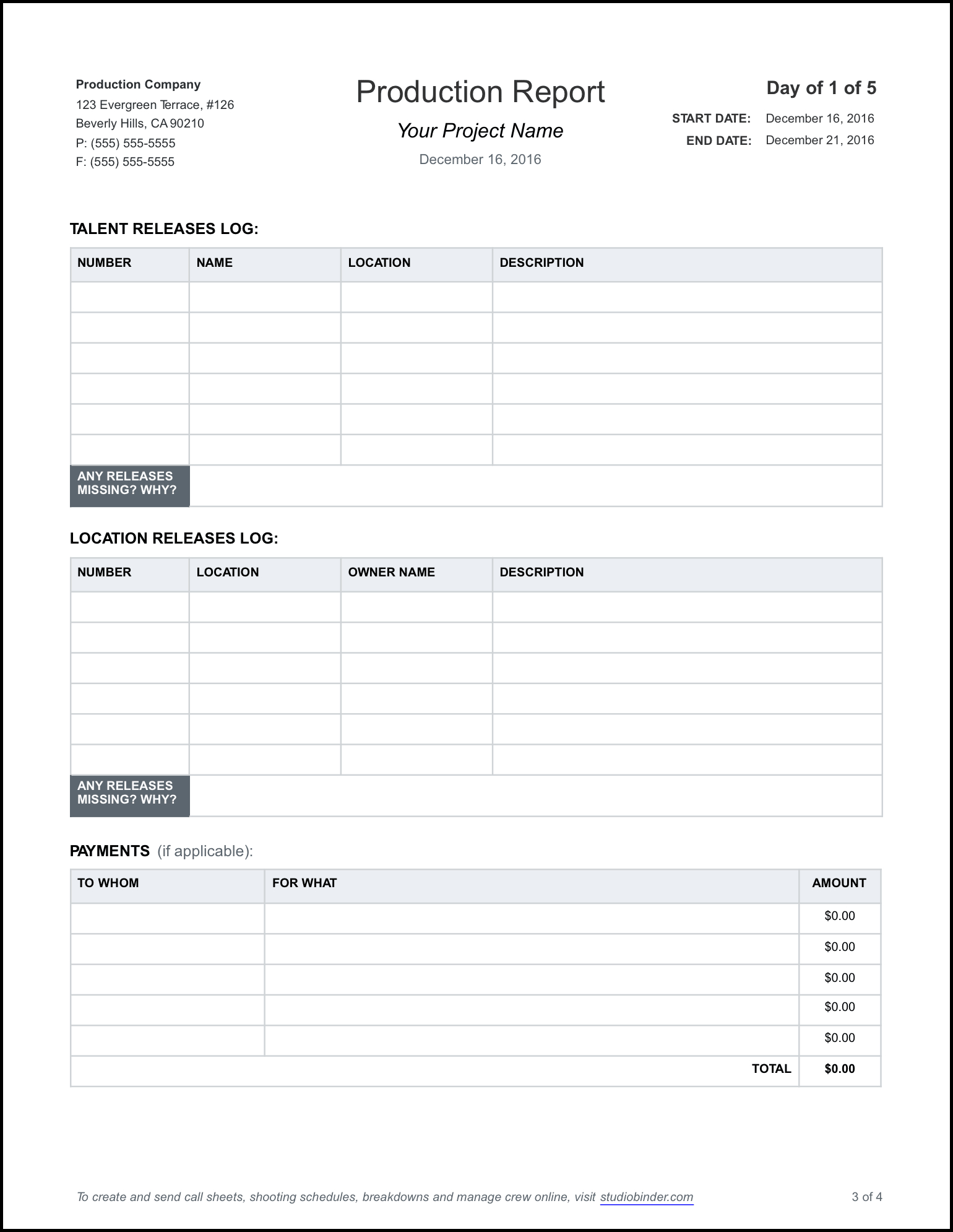

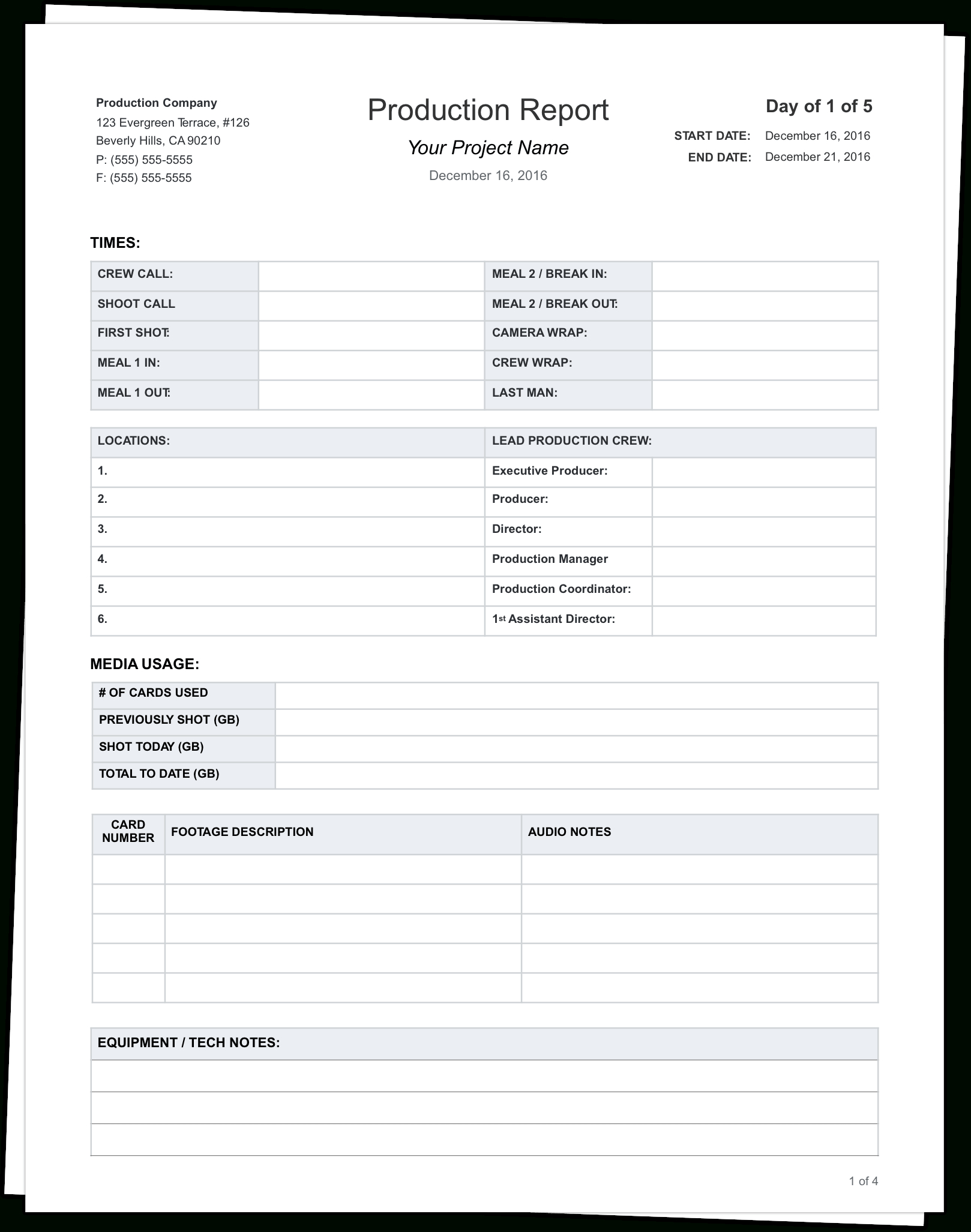

Project-Based Production Report (e.g., Film, Software)

This template is structured around a project with a defined start and end, such as a film production, a construction project, or a software release.

* Key Sections: Project Health Summary, Phase Completion Status, Milestone Tracker (Planned vs. Actual Dates), Budget Burn Rate, Resource Allocation, Risk Register, and Change Log.

* Purpose: To track progress against a project plan and manage the “triple constraint” of scope, time, and budget.

Best Practices for Writing and Using Production Reports

A great template is only half the battle. How you complete and use the report is what truly determines its value.

- Be Objective and Data-Driven: Base your report on facts and metrics, not opinions or feelings. Instead of saying “production was slow,” say “production was at 85% of the target due to a 45-minute conveyor belt stoppage.”

- Keep it Concise: Your audience is busy. Use bullet points, short sentences, and visual aids like charts. Avoid jargon and long, narrative paragraphs. Get straight to the point.

- Be Honest and Transparent: It can be tempting to downplay problems, but hiding bad news is a recipe for disaster. Surfacing issues early and transparently builds trust and allows the team to swarm the problem before it grows.

- Maintain a Consistent Cadence: Whether your report is daily, weekly, or bi-weekly, deliver it on time, every time. Consistency makes the report a reliable and expected part of the workflow.

- Focus on the “So What?”: Don’t just present data; interpret it. If the defect rate is up by 5%, explain the likely cause and what action is being taken to address it. Your analysis is what turns data into actionable intelligence.

Conclusion

A well-crafted Production Status Report Template is more than just an administrative task; it is a strategic asset. It transforms ambiguous, chaotic communication into a clear, efficient, and consistent flow of information. By providing a single source of truth, it aligns teams, empowers managers, and gives stakeholders the confidence that production is being managed proactively and professionally. The investment in creating and standardizing a template pays for itself many times over in saved time, reduced errors, and improved decision-making.

Whether you are managing a factory floor, a software development team, or a creative project, the principles remain the same. Start by identifying your audience and goals, build a template with the essential components, and foster a culture of transparent, data-driven reporting. By embracing this structured approach, you can move from constantly reacting to production fires to strategically steering your operations toward consistent and predictable success.

]]>