Effectively managing workplace and project safety requires a systematic approach to identifying, analyzing, and mitigating risks. A cornerstone of this process is a comprehensive document that outlines potential hazards and the strategies to control them, and using a Safety Analysis Report Template is the most efficient way to achieve this. This structured framework ensures that no critical element is overlooked, providing a clear and consistent method for evaluating safety from the initial design phase through to operation and decommissioning. By standardizing the reporting process, organizations can not only enhance safety but also improve communication among stakeholders, ensure regulatory compliance, and create a robust safety culture.

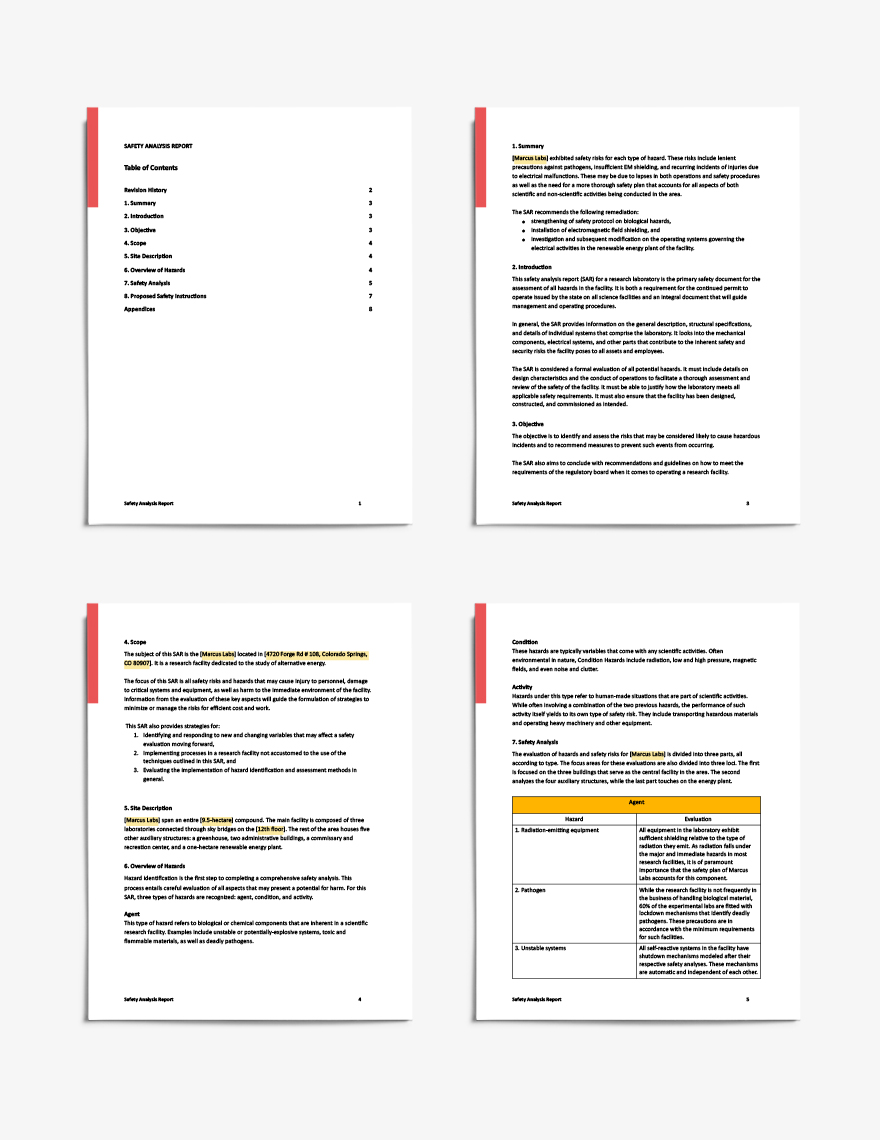

A Safety Analysis Report (SAR), sometimes known as a Safety Case, is a formal document that provides a detailed argument that a system, facility, or process is acceptably safe for a specific application within a defined environment. It’s not merely a checklist of potential problems; it’s a dynamic and thorough investigation into what could go wrong, the likelihood and severity of such events, and the preventative or protective measures in place. The report serves as a critical communication tool for project managers, engineers, safety officers, and regulatory bodies, demonstrating that due diligence has been performed and that risks are managed to an As Low As Reasonably Practicable (ALARP) level.

The true value of a standardized template lies in its ability to transform a complex and potentially daunting task into a manageable and repeatable process. Instead of starting from a blank page for every new project or analysis, teams can leverage a pre-defined structure that guides them through each necessary step. This not only saves significant time and resources but also promotes a higher level of quality and consistency across all safety assessments. This article will delve into the essential components of a robust safety analysis report, explore different analysis techniques, and provide guidance on how to effectively implement and customize a template for your specific needs.

What is a Safety Analysis Report?

A Safety Analysis Report (SAR) is a formal, comprehensive document that systematically identifies the hazards associated with a particular system, process, operation, or facility. Its primary purpose is to assess the risks posed by these hazards and to detail the control measures and mitigation strategies that have been implemented to ensure an acceptable level of safety. Essentially, it presents a compelling safety case, demonstrating to all stakeholders—including management, employees, and regulatory agencies—that safety has been thoroughly considered and that all reasonable steps have been taken to prevent accidents, injuries, and damage.

The scope of an SAR can vary widely depending on the industry and the complexity of the system under review. In high-hazard industries like nuclear power, aerospace, and chemical manufacturing, these reports are often extensive, legally mandated documents that are subject to rigorous regulatory scrutiny. In other sectors, such as construction or general manufacturing, the report might take the form of a Job Hazard Analysis (JHA) or a project-specific safety plan. Regardless of its name or scope, the core function remains the same: to proactively manage risk.

The preparation of a SAR is typically a collaborative effort led by safety engineers or qualified safety professionals. However, it requires input from a multidisciplinary team, including design engineers, operators, maintenance personnel, and project managers. This collaborative approach ensures that the analysis is comprehensive and reflects a deep understanding of both the technical aspects of the system and its real-world operational context. The final report becomes a living document, often updated throughout the lifecycle of the system to reflect changes in design, operating procedures, or regulatory requirements.

The Core Components of a Safety Analysis Report Template

A well-structured template is the foundation of an effective and efficient safety analysis process. It acts as a guide and a checklist, ensuring all critical areas are addressed consistently. While the specific details may vary by industry, a comprehensive Safety Analysis Report Template will almost always include the following core components.

Executive Summary

This section provides a high-level overview of the entire report. It is typically written last but placed at the beginning for the convenience of senior managers and stakeholders who may not have the time to read the full document. The executive summary should concisely state the purpose of the analysis, the scope of the system reviewed, the most significant risks identified, and the key conclusions and recommendations for risk mitigation.

System or Process Description

Before hazards can be identified, the system or process being analyzed must be clearly defined. This section provides a detailed description, including its purpose, boundaries, and main components. It should cover how the system operates, the environment it operates in, and the personnel who interact with it. The use of diagrams, process flow charts, and architectural drawings is highly encouraged to provide clarity and context. A thorough description is crucial because an incomplete understanding of the system will inevitably lead to an incomplete hazard analysis.

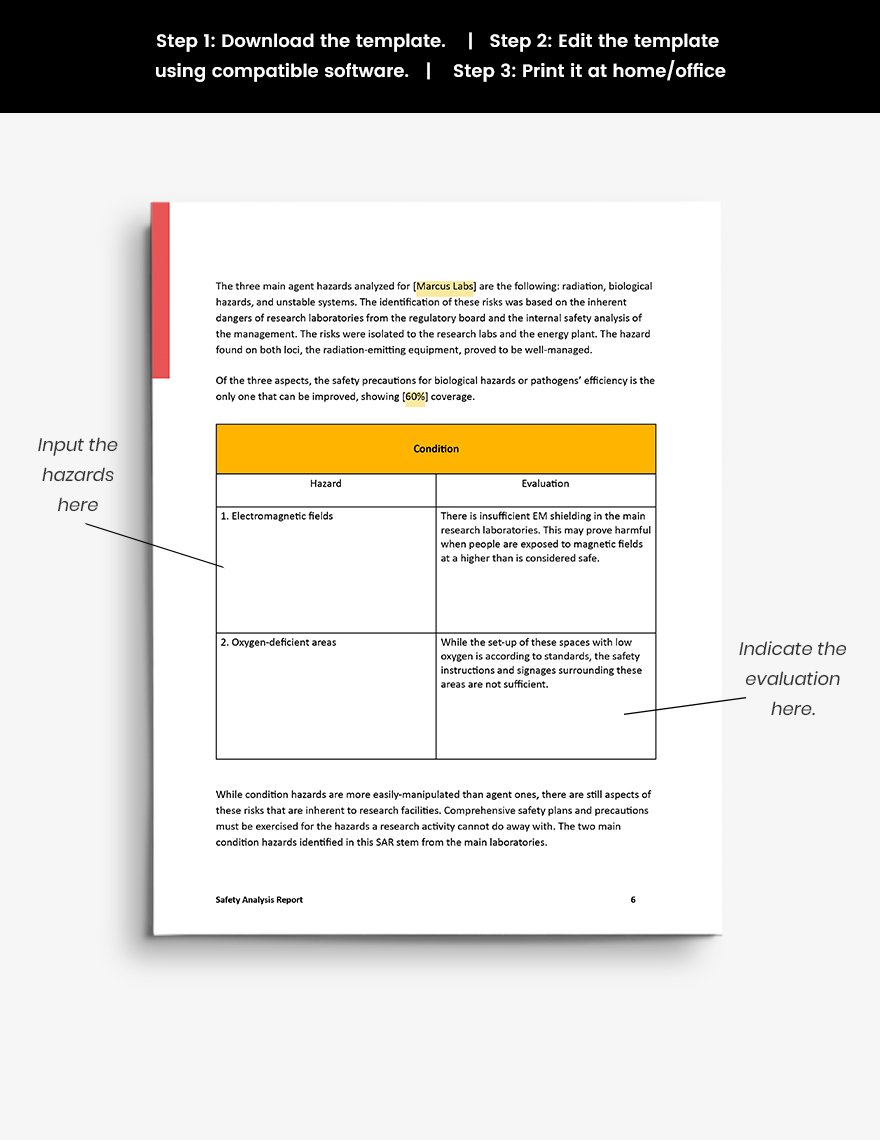

Hazard Identification

This is the heart of the safety analysis. This section details the methods used to systematically identify potential hazards. A hazard is any source of potential harm, damage, or adverse health effects. The report should list every identified hazard, from equipment failure and human error to external environmental factors. Common techniques used for hazard identification, such as HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), or What-If analysis, should be described. Each hazard should be clearly documented with information about its potential causes and consequences.

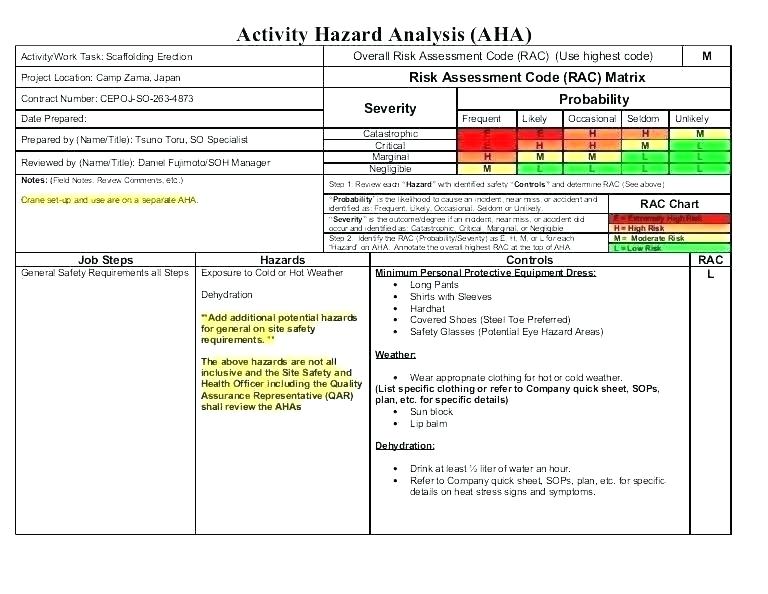

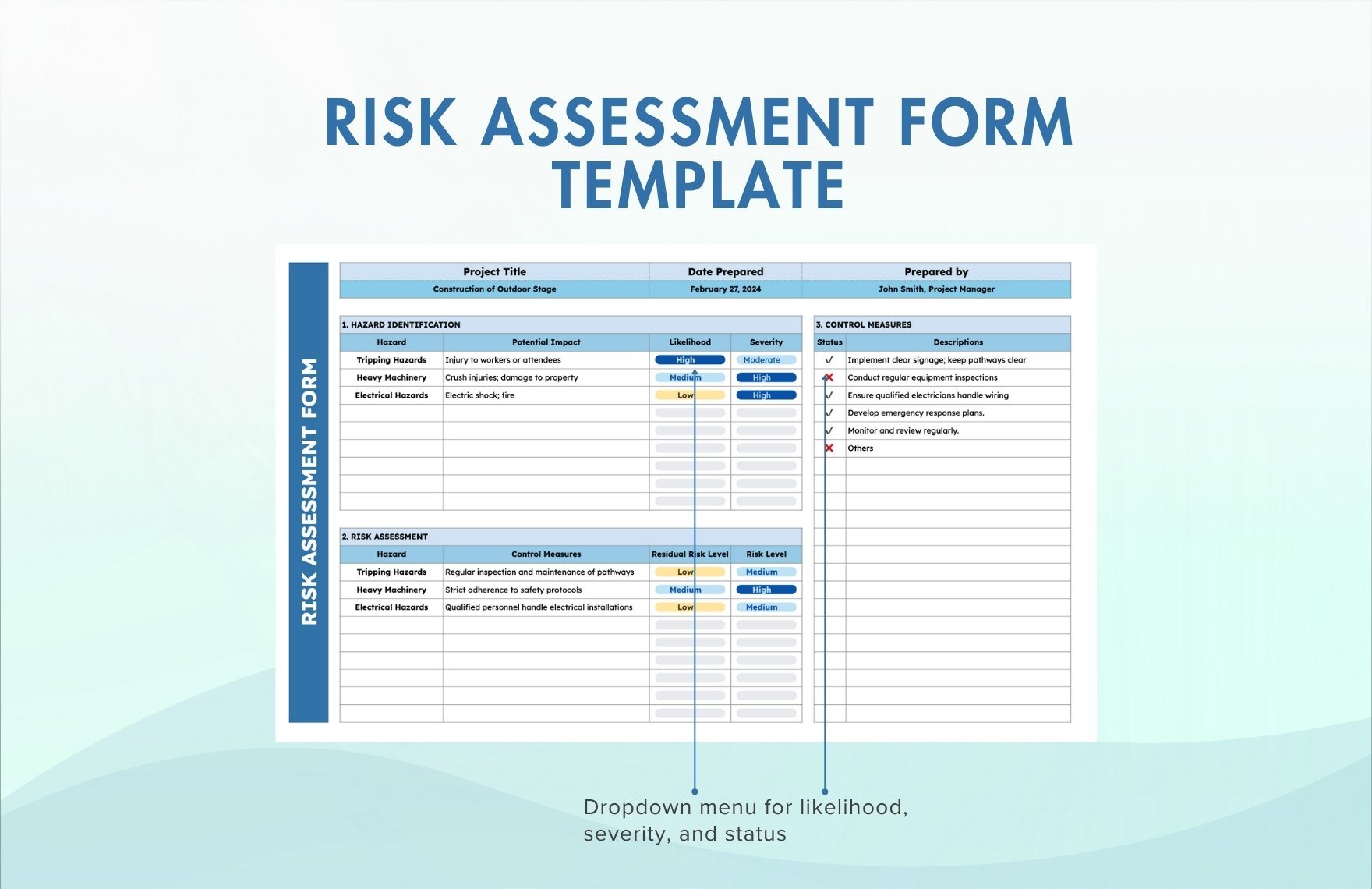

Risk Assessment and Analysis

Once hazards are identified, the next step is to assess the level of risk associated with each one. Risk is a combination of the likelihood of a hazardous event occurring and the severity of its potential consequences. This section typically uses a risk matrix to qualitatively or quantitatively score each risk. For example, likelihood might be ranked from “Rare” to “Frequent,” and severity from “Negligible” to “Catastrophic.” The resulting risk level (e.g., Low, Medium, High, Critical) helps prioritize which hazards require the most urgent attention.

Mitigation and Control Measures

This section outlines the specific actions and strategies designed to eliminate or reduce the identified risks to an acceptable level. Control measures are often categorized according to the hierarchy of controls:

1. Elimination: Physically remove the hazard.

2. Substitution: Replace the hazard with a less hazardous alternative.

3. Engineering Controls: Isolate people from the hazard (e.g., machine guards, ventilation systems).

4. Administrative Controls: Change the way people work (e.g., safety procedures, training, warning signs).

5. Personal Protective Equipment (PPE): Protect the worker with equipment like safety glasses, gloves, or respirators.

For each high-priority risk, specific, actionable control measures should be detailed, including who is responsible for implementation and the deadline for completion.

Verification, Validation, and Monitoring

A safety report is not complete once control measures are proposed. This section describes how the effectiveness of these controls will be verified and validated. It outlines the testing procedures, inspections, and audits that will be conducted to ensure the controls work as intended. It also details the ongoing monitoring processes that will be put in place to track safety performance and ensure that the controls remain effective over time.

Appendices

The appendices contain supplementary information that supports the main body of the report. This can include raw data from the analysis, detailed calculations, technical drawings, meeting minutes from hazard review sessions, team member qualifications, and references to applicable standards and regulations.

Key Safety Analysis Techniques to Inform Your Report

The quality of a Safety Analysis Report depends heavily on the thoroughness of the underlying analysis. Different techniques are suited for different applications, and the chosen method will shape the content of the report. Understanding these techniques helps in selecting the right approach for your specific needs.

Hazard and Operability Study (HAZOP)

A HAZOP is a highly structured and systematic examination of a planned or existing process or operation. It is most often used in process industries like chemical manufacturing and oil and gas. A multidisciplinary team uses a set of “guide words” (e.g., No, More, Less, Reverse) to brainstorm potential deviations from the design intent of the system and identify their causes and consequences. The findings from a HAZOP directly populate the hazard identification and risk assessment sections of the SAR.

Failure Mode and Effects Analysis (FMEA)

FMEA is a bottom-up, systematic technique for identifying potential failure modes in a product, system, or process. For each component, the team identifies how it could fail, what the effects of that failure would be, and how severe those effects are. It often includes calculating a Risk Priority Number (RPN) to prioritize mitigation efforts. FMEA is widely used in manufacturing, automotive, and aerospace industries and provides a detailed, component-level analysis for the SAR.

Fault Tree Analysis (FTA)

In contrast to FMEA, Fault Tree Analysis (FTA) is a top-down, deductive failure analysis. It starts with a specific undesirable top-level event (e.g., an explosion) and works backward to identify all the potential contributing factors and component failures that could lead to that event. FTA is a powerful graphical tool for understanding complex system interactions and calculating the probability of a catastrophic failure, providing quantitative risk data for the SAR.

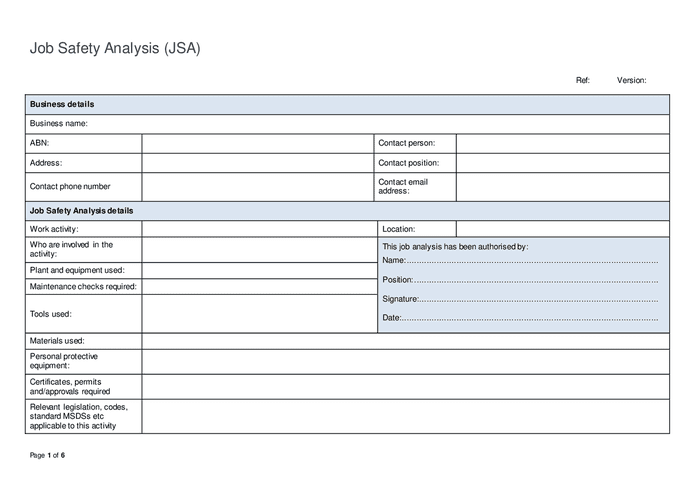

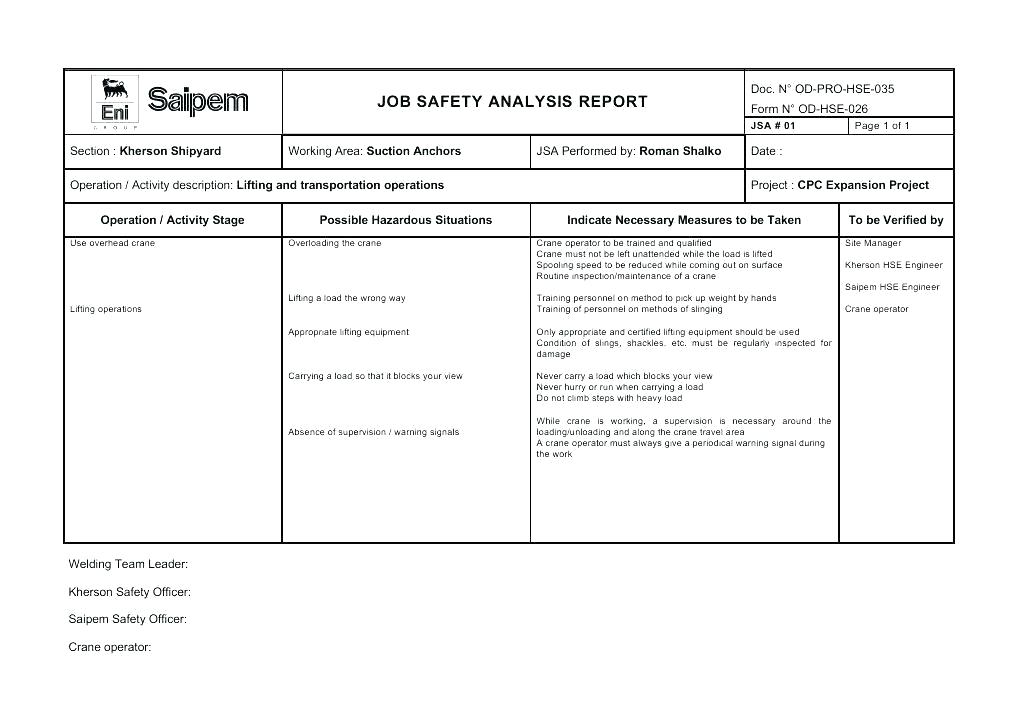

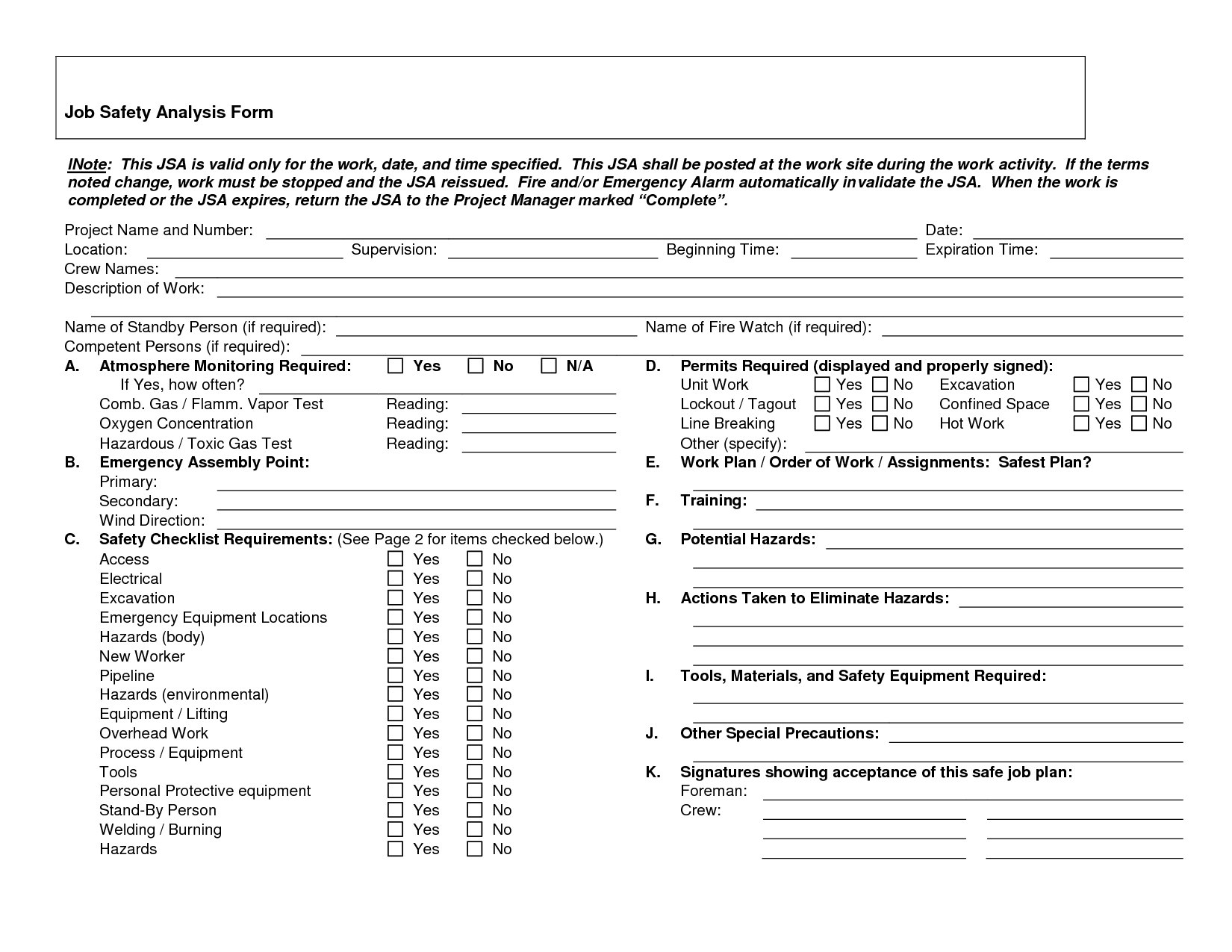

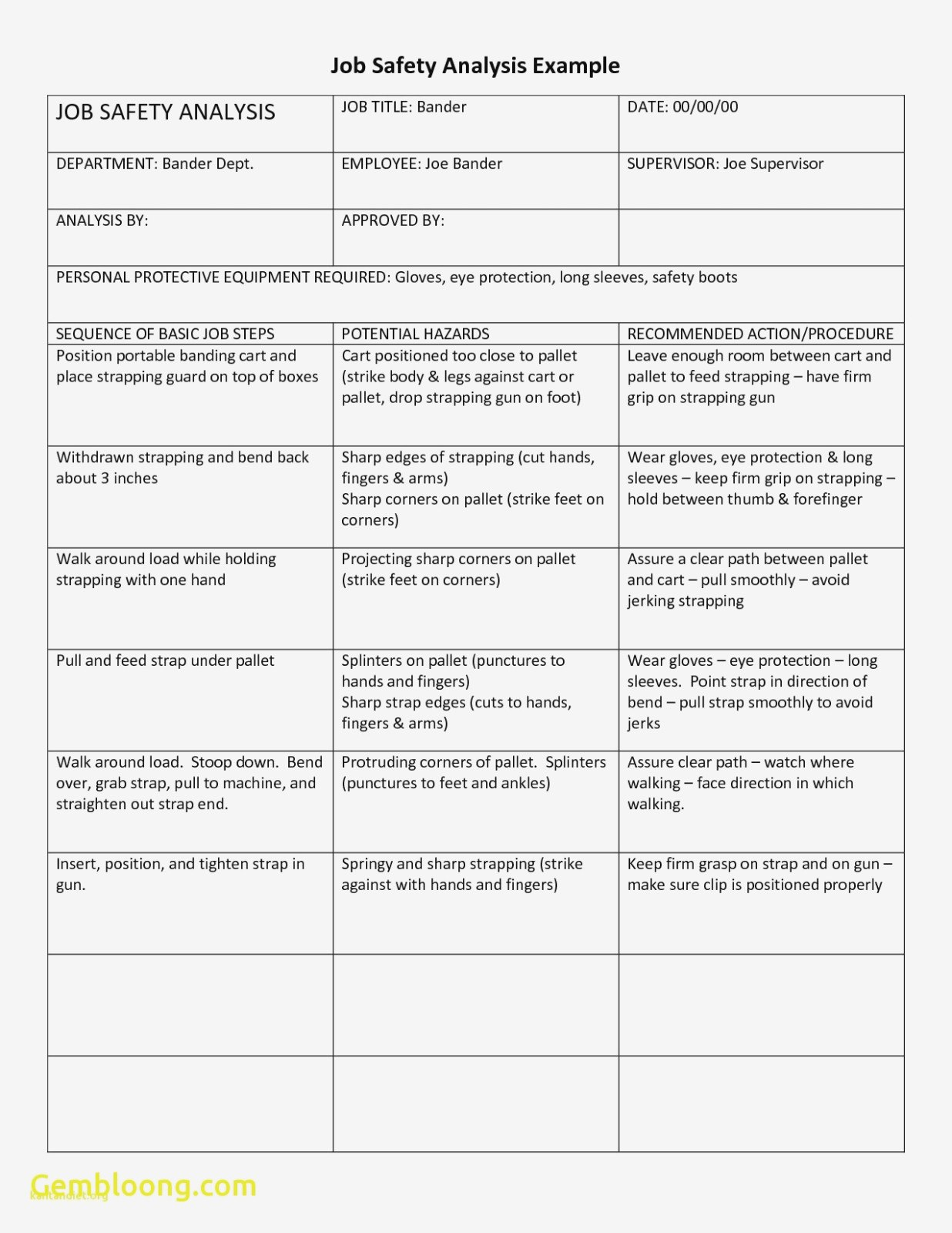

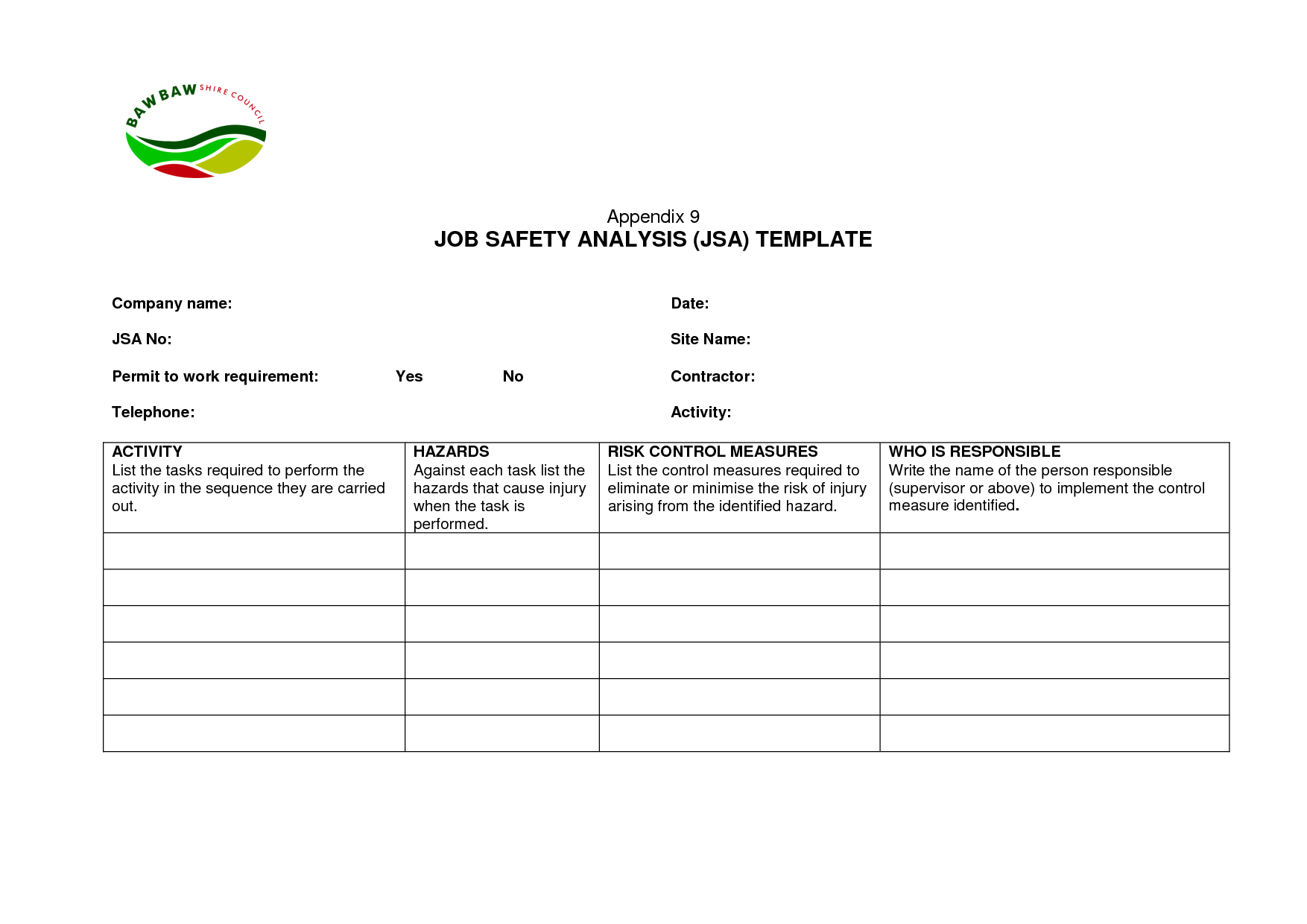

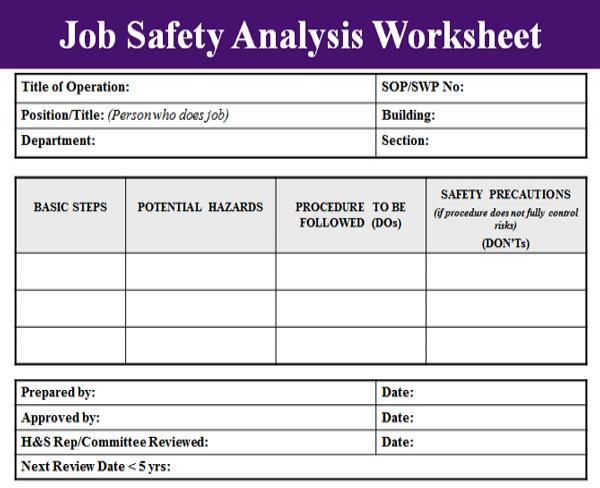

Job Safety Analysis (JSA) or Job Hazard Analysis (JHA)

A JSA or JHA is focused on a specific job or task rather than an entire system. It involves breaking a job down into a sequence of steps, identifying the potential hazards associated with each step, and determining the safest way to perform the job. This technique is extremely common in construction and general industry and is a practical way to develop safe work procedures. The JSA document itself can be a simplified form of a safety report or be included as a key input into a larger project SAR.

The Benefits of Using a Standardized Template

Adopting a standardized template for safety analysis reporting offers numerous advantages that go beyond simple convenience. It is a strategic move that can significantly enhance an organization’s overall safety management system.

- Consistency and Standardization: A template ensures that every safety report across the organization follows the same structure and includes the same critical information. This consistency makes it easier to compare risks across different projects or departments and ensures a uniform standard of quality.

- Efficiency and Time Savings: Building a comprehensive report from scratch is time-consuming. A template provides a ready-made framework, allowing the safety team to focus their efforts on the analysis itself rather than on formatting and structure. This accelerates the reporting process, especially for recurring analyses.

- Ensuring Completeness: A well-designed template functions as a checklist. It guides the author through all the necessary sections, reducing the risk that a crucial element—like verification of control measures or a description of the operational context—is accidentally omitted.

- Improved Communication and Clarity: A standardized format makes the report more accessible and easier to understand for all stakeholders, from frontline workers to executive management and external auditors. Everyone knows where to find the information they need, facilitating better decision-making and alignment.

- Facilitating Compliance: Many industries are governed by strict safety regulations (e.g., OSHA, EPA, FAA). A template can be designed to explicitly address all regulatory requirements, making it easier to demonstrate compliance during audits and inspections.

Customizing and Implementing Your Template

While a standard template provides a great starting point, it must be adapted to fit the specific context of your organization and industry. A one-size-fits-all approach is rarely effective in safety management.

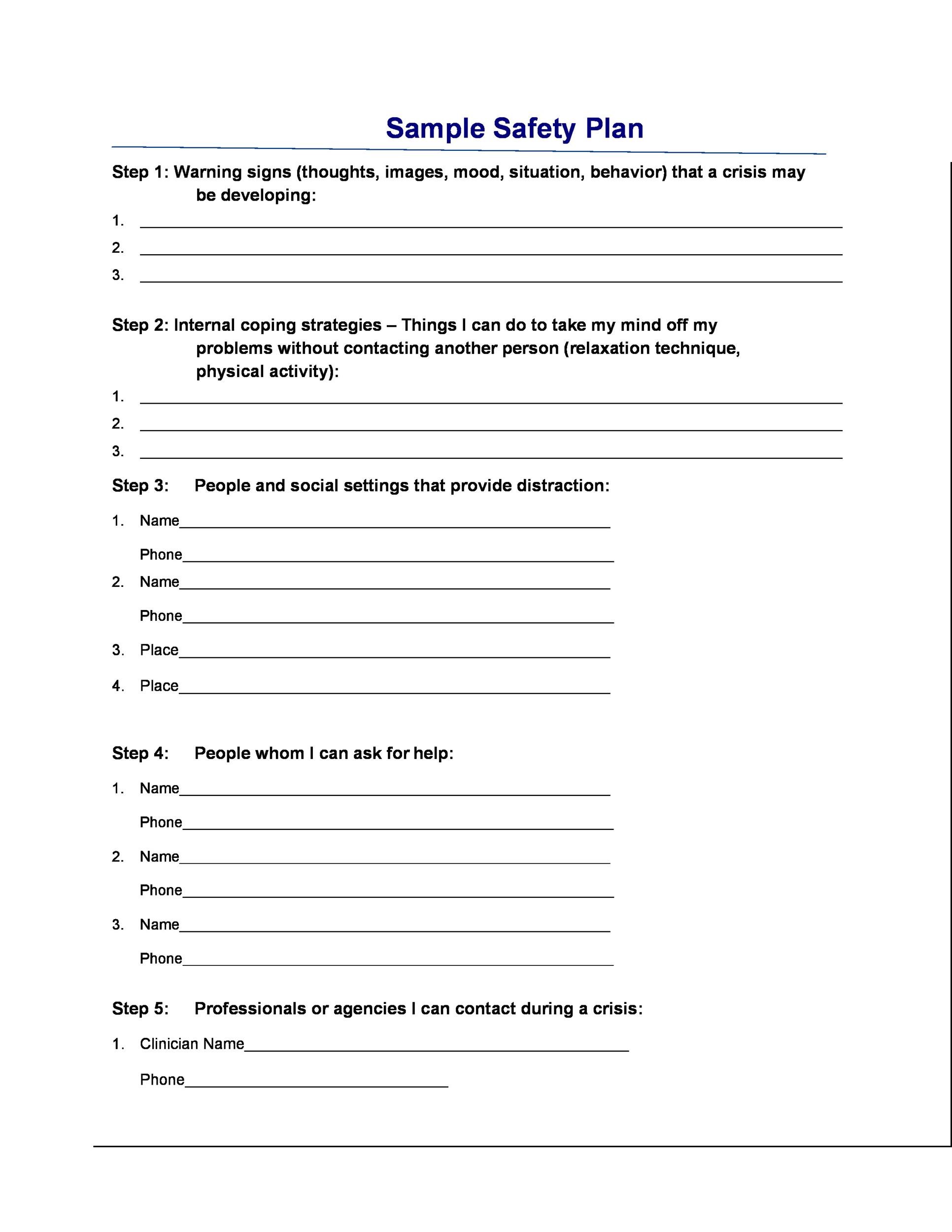

Tailor the Template to Your Specific Needs

The first step is to customize the generic template. A safety report for a construction site will have different areas of focus than one for a software system controlling a medical device. Consider your industry’s specific hazards, terminology, and regulatory landscape. Add or remove sections as needed. For example, you might add a section on environmental impact or specific regulatory compliance checklists relevant to your operations.

Integrate with Your Safety Management System (SMS)

The Safety Analysis Report should not be a standalone document. It should be an integral part of your organization’s overall Safety Management System (SMS). Ensure the template’s workflow aligns with your existing processes for incident reporting, change management, and continuous improvement. The findings from the SAR should feed directly into action tracking systems and be used to update training materials and safe work procedures.

Train Your Team

A template is only as good as the people who use it. Provide thorough training to everyone who will be involved in preparing or reviewing safety reports. This training should cover not only how to fill out the template but also the underlying principles of hazard identification and risk assessment. This ensures that the analysis is robust and the reports are of high quality.

Choose the Right Format: Digital vs. Paper

Consider whether a digital or paper-based template is best for your team. Digital templates, created using software platforms or even shared documents, offer significant advantages. They are easier to store, share, and update. Many safety management software solutions come with built-in, customizable report templates that can automatically track actions, send reminders, and generate analytics dashboards, creating a more dynamic and effective safety ecosystem.

Conclusion

A well-crafted Safety Analysis Report is an indispensable tool for proactively managing risk and fostering a strong safety culture. It provides a structured, evidence-based argument that a system or process is safe for its intended use. By leveraging a Safety Analysis Report Template, organizations can bring consistency, efficiency, and thoroughness to this critical process. A template ensures that all essential components—from system description and hazard identification to risk assessment and control measure verification—are systematically addressed every time.

The benefits of this structured approach are clear: it saves time, improves communication, facilitates regulatory compliance, and most importantly, helps prevent accidents. However, it’s crucial to remember that a template is a guide, not a substitute for rigorous analysis and critical thinking. The template must be customized to the specific context of the industry and organization, and the team using it must be well-trained in the principles of safety management. By embracing a standardized yet flexible approach to safety reporting, organizations can better protect their people, assets, and reputation, turning safety from a matter of compliance into a genuine competitive advantage.

]]>