Effective engineering practices hinge on thorough documentation, ensuring every aspect of a project, from initial design to final implementation and ongoing maintenance, meets stringent standards. A well-structured Engineering Inspection Report Template serves as the backbone of this documentation, providing a standardized framework for capturing critical observations, findings, and recommendations. It transforms complex technical assessments into clear, actionable insights, indispensable for project managers, engineers, and stakeholders alike. Without such a template, vital information could be overlooked, leading to inconsistencies, potential safety hazards, and costly reworks.

The meticulous process of engineering inspection is designed to identify deficiencies, assess structural integrity, verify compliance with codes and specifications, and ensure the overall quality and safety of engineered systems and components. Whether it’s a routine maintenance check, a pre-commissioning verification, or a post-incident investigation, the quality of the inspection report directly impacts decision-making. A standardized template elevates the efficiency and accuracy of this reporting, minimizing subjective interpretations and maximizing clarity.

Moreover, in an industry where accountability and precision are paramount, a comprehensive report template acts as a legal and historical record. It provides irrefutable evidence of due diligence, serves as a reference for future audits, and contributes to a robust knowledge base for continuous improvement. For companies striving for operational excellence and regulatory compliance, the adoption of a robust, universally understood template is not merely beneficial; it’s a strategic imperative. It empowers teams to conduct inspections with confidence, knowing their findings will be consistently presented and easily understood by all relevant parties.

Why is an Engineering Inspection Report Essential?

An engineering inspection report is far more than a simple checklist; it is a critical communication tool that bridges the gap between on-site observations and strategic decisions. Its primary purpose is to document the condition of a structure, system, or component at a specific point in time, identifying any deviations from expected performance, design specifications, or regulatory standards. This documentation is crucial for several reasons, impacting safety, financial viability, and operational continuity.

Firstly, these reports are fundamental for safety assurance. By pinpointing potential failures, structural weaknesses, or operational hazards, they allow for timely interventions, preventing accidents, injuries, and catastrophic damage. Secondly, they serve as a cornerstone for quality control and assurance, ensuring that construction, manufacturing, and maintenance activities adhere to the highest industry standards and client expectations. This proactive identification of non-conformities saves significant time and resources in the long run.

Beyond safety and quality, inspection reports are vital for asset management and longevity. Regular inspections documented through precise reports enable organizations to track the wear and tear of assets, predict maintenance needs, and schedule repairs or replacements proactively. This extends the lifespan of expensive equipment and infrastructure, optimizing return on investment. Furthermore, in the event of disputes, legal claims, or insurance assessments, a detailed inspection report provides objective evidence, protecting all parties involved.

Key Components of an Effective Engineering Inspection Report Template

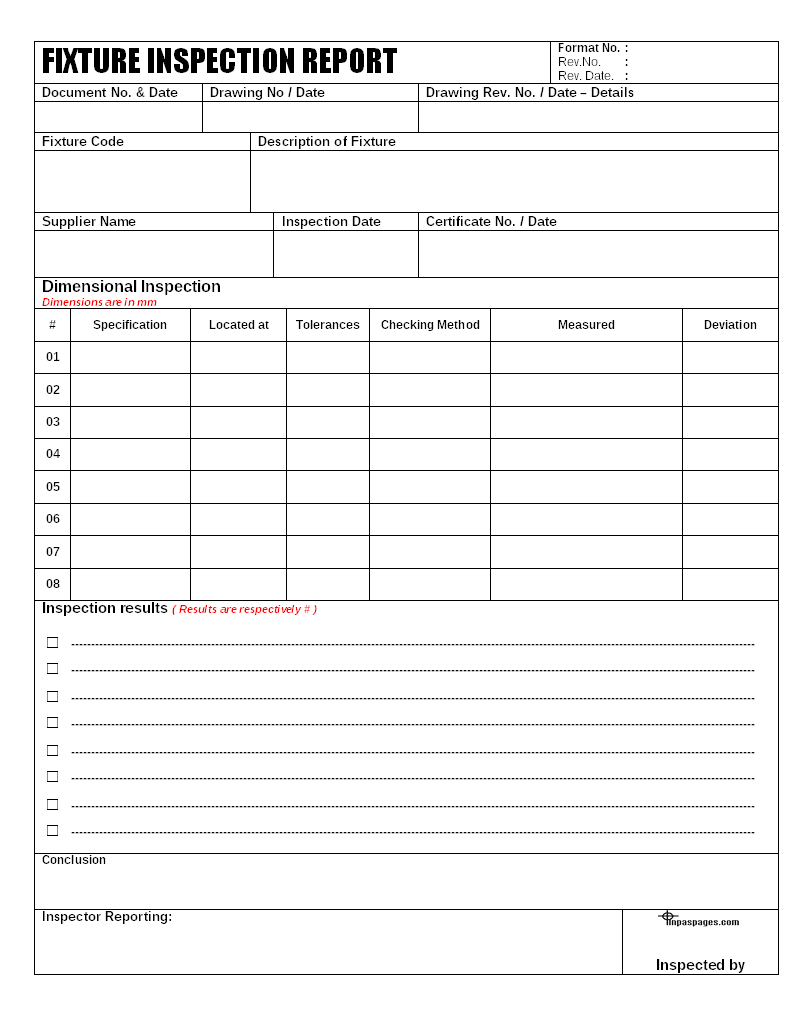

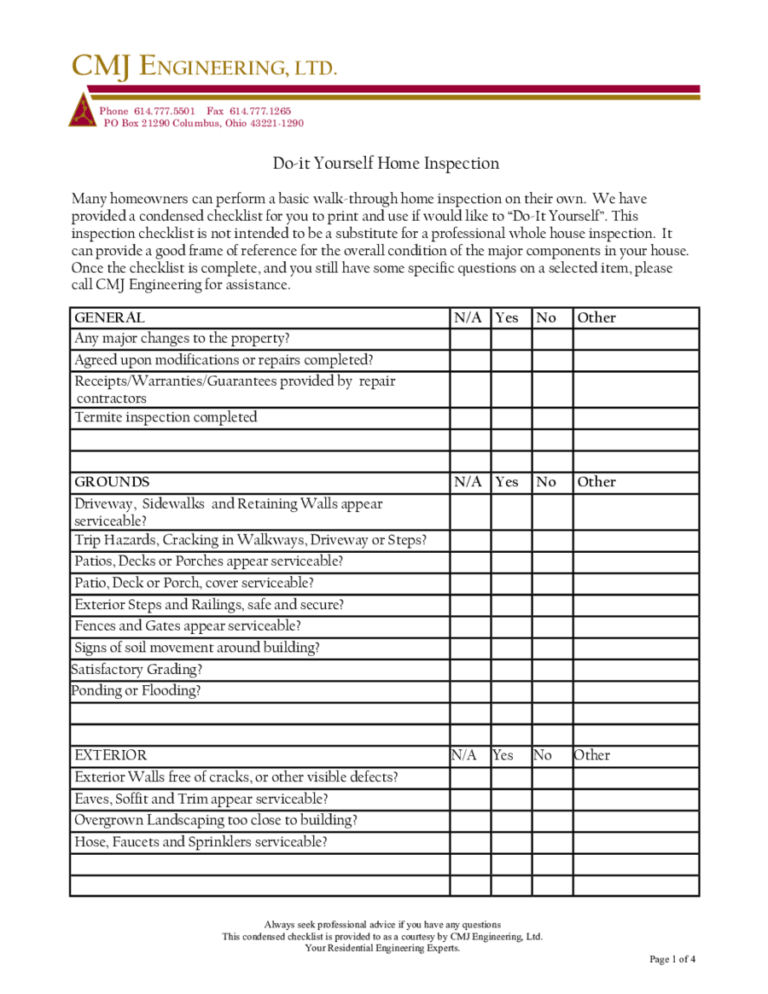

A truly effective Engineering Inspection Report Template must be comprehensive, logical, and user-friendly, guiding the inspector through every necessary detail while allowing for specific observations. The structure should facilitate both the collection of data and its subsequent interpretation.

Project and Administrative Details

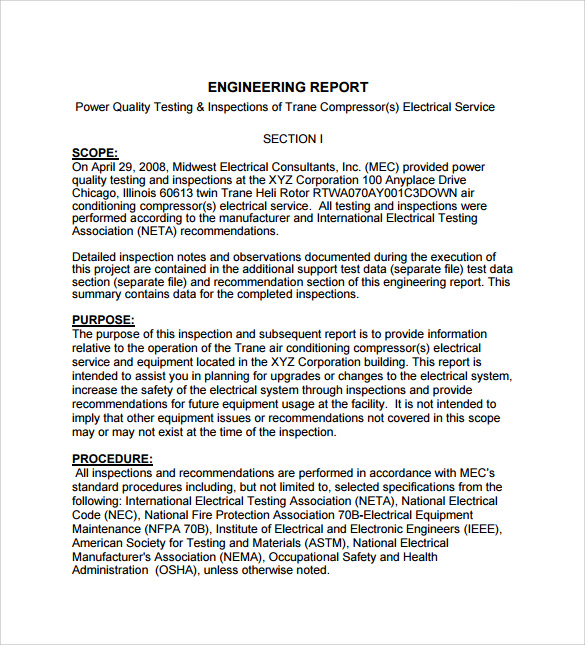

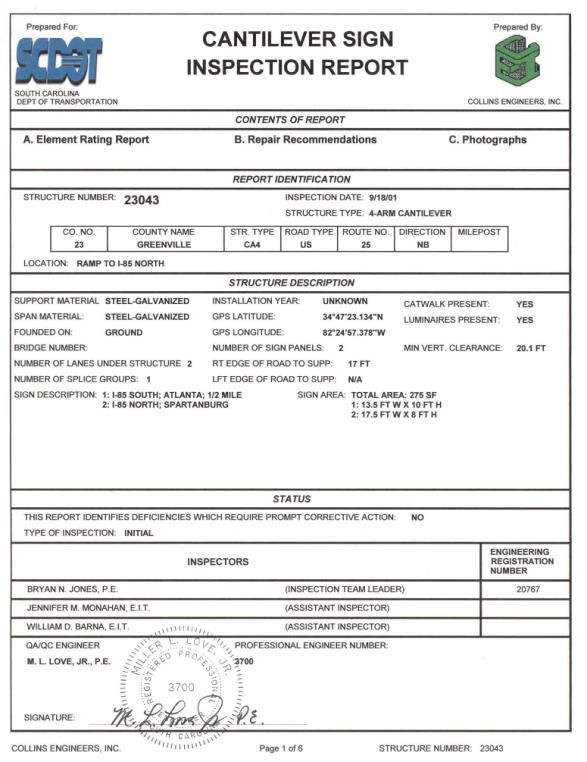

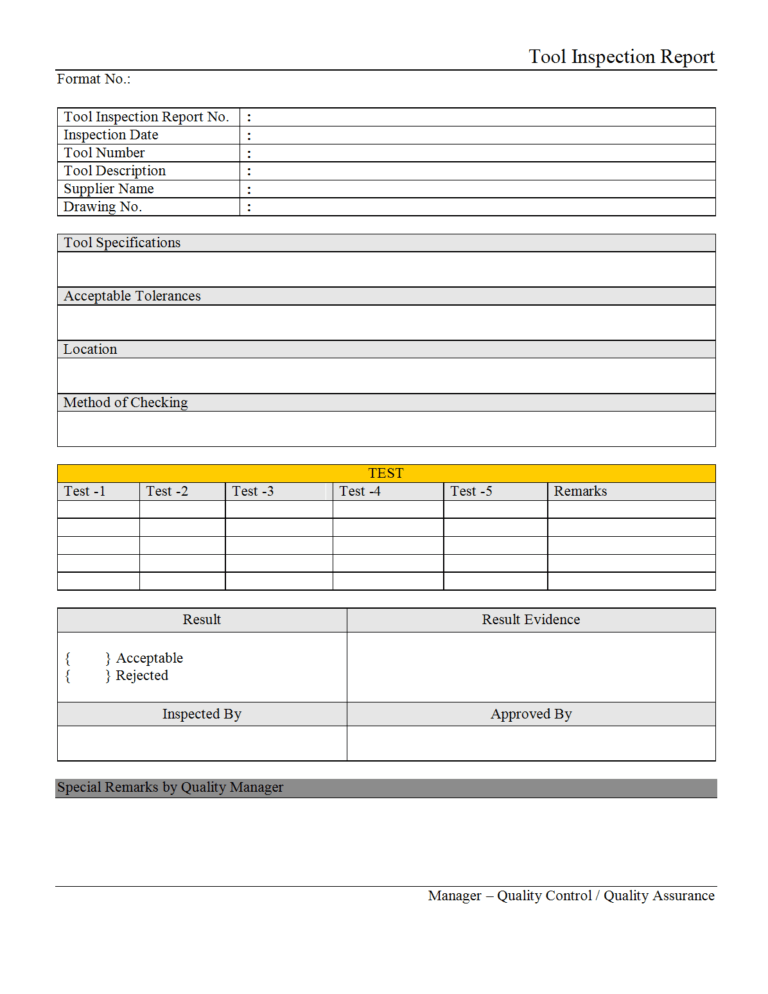

Every report must begin with essential identifying information. This includes the project name and number, inspection date and time, location of the inspection, and the name and contact information of the inspector(s). It should also specify the client or responsible party and any relevant reference numbers or permit IDs.

Scope of Inspection

Clearly defining the scope of the inspection is paramount. This section outlines what was inspected, what was excluded, and the specific objectives of the inspection (e.g., structural integrity assessment, electrical system check, compliance audit). It sets the boundaries and expectations for the report’s content.

Observations and Findings

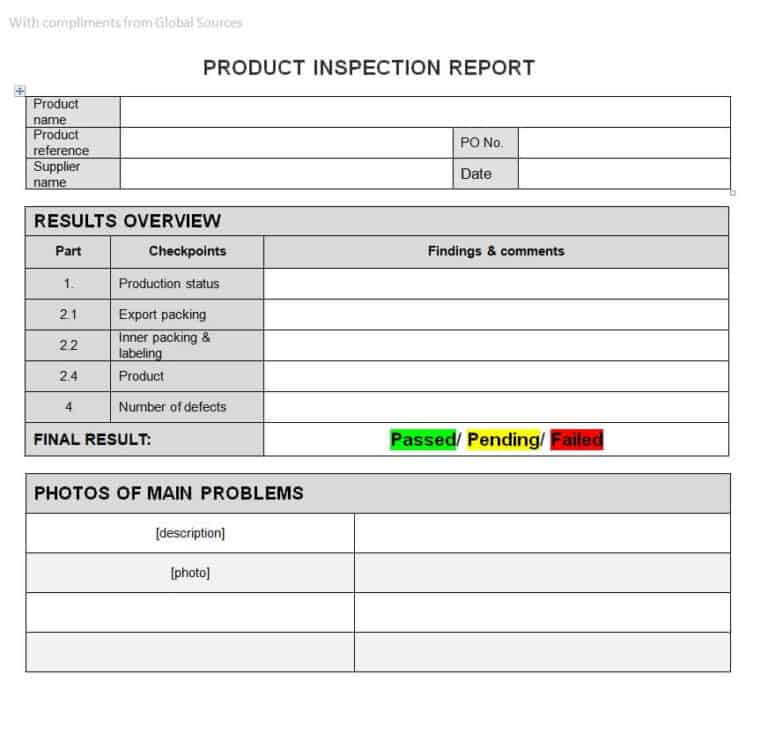

This is the core of the report, detailing what was observed during the inspection. It should be highly descriptive, objective, and factual. Observations can include:

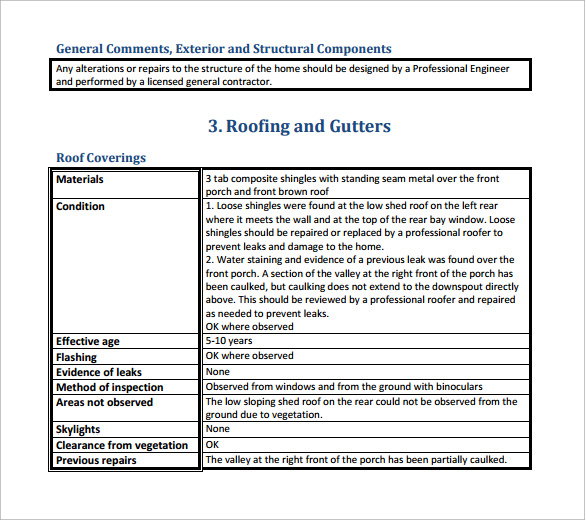

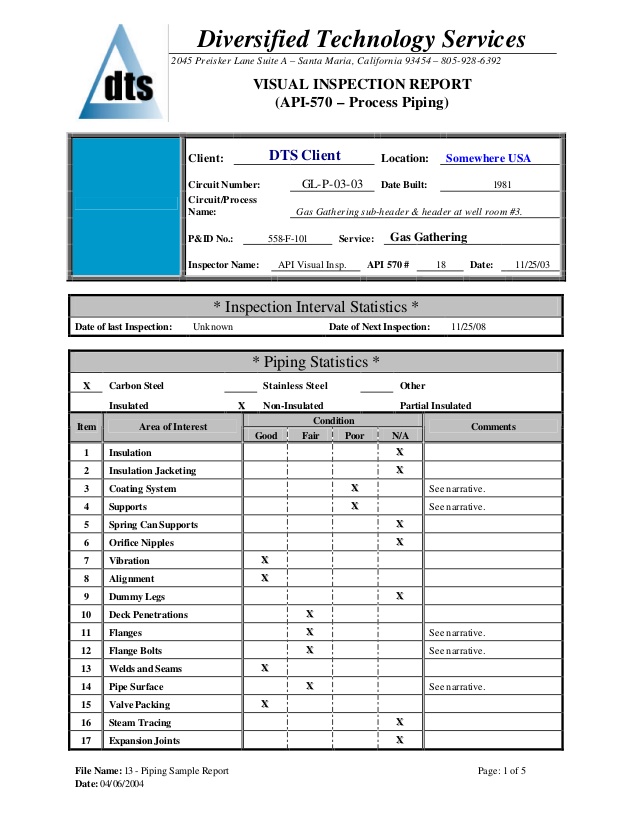

- Existing Conditions: A description of the current state of the inspected item, including general appearance, materials, and any initial observations.

- Deficiencies/Non-Conformities: Specific issues identified, such as cracks, corrosion, leaks, faulty wiring, or deviations from design. Each finding should be clearly described, located, and, if possible, quantified.

- Compliance Status: Assessment against relevant codes, standards (e.g., ASME, ASTM, ISO), and regulatory requirements.

- Photographic Evidence: Integrated or referenced images and videos are crucial. Each piece of visual evidence should be captioned, dated, and linked directly to the corresponding observation.

Analysis and Assessment

Following the observations, this section provides an engineering analysis of the findings. It might include:

- Root Cause Analysis: Where possible, an explanation of why a deficiency or failure occurred.

- Risk Assessment: Evaluation of the potential impact and likelihood of identified issues, classifying them by severity (e.g., critical, major, minor).

- Impact Assessment: Discussion of how the findings affect safety, performance, operational efficiency, or regulatory compliance.

Recommendations and Corrective Actions

Based on the analysis, this section proposes concrete solutions. Recommendations should be clear, actionable, and prioritized. This might involve:

- Immediate Actions: Steps required to mitigate urgent risks.

- Short-Term Solutions: Repairs, adjustments, or temporary fixes.

- Long-Term Solutions: Major overhauls, replacements, or design modifications.

- Follow-Up Requirements: Details on subsequent inspections or monitoring.

- Responsible Parties and Deadlines: Assigning ownership and setting timelines for corrective actions.

Conclusion and Signatures

The report concludes with a concise summary of the most critical findings and recommendations. It should also include a disclaimer regarding the limitations of the inspection and spaces for inspector signatures, client acceptance, and reviewers’ endorsements, along with their respective dates.

Types of Engineering Inspections Benefiting from a Template

The utility of a standardized Engineering Inspection Report Template extends across numerous engineering disciplines and inspection scenarios. Each type of inspection, while having unique requirements, benefits immensely from a consistent reporting structure.

Structural Inspections

Whether assessing bridges, buildings, or industrial facilities, structural inspections evaluate integrity, material degradation, and compliance with building codes. Templates for these inspections often include sections for foundation observations, framing analysis, facade condition, and load-bearing element assessment.

Mechanical Inspections

These focus on machinery, HVAC systems, pipelines, and other mechanical components. Reports for mechanical inspections detail operational performance, wear and tear, lubrication, alignment, and adherence to maintenance schedules.

Electrical Inspections

Covering wiring, circuit breakers, control panels, and electrical safety systems, these inspections ensure compliance with electrical codes, identify fire hazards, and confirm proper functionality. Templates help document continuity tests, insulation resistance, and grounding checks.

Civil Engineering Inspections

Roads, dams, drainage systems, and public infrastructure fall under civil engineering inspections. Reports here might cover pavement conditions, erosion control, hydrological observations, and soil stability.

Quality Control and Assurance Inspections

Throughout manufacturing processes or construction phases, these inspections verify that products and installations meet specified quality standards and design tolerances. Templates are invaluable for documenting material conformity, dimensional accuracy, and workmanship.

Pre-Commissioning and Commissioning Inspections

Before a system or facility becomes operational, pre-commissioning inspections ensure all components are correctly installed and tested. Commissioning inspections then verify the system’s performance against design criteria. Templates guide the detailed checks required for successful handover.

Forensic Engineering Inspections

In cases of failure, accident, or dispute, forensic inspections determine the cause. These reports are highly detailed, often involving complex analysis and reconstruction, where a template ensures all evidentiary aspects are captured systematically.

Benefits of Using a Standardized Engineering Inspection Report Template

The adoption of a standardized Engineering Inspection Report Template offers a myriad of benefits that enhance efficiency, improve quality, and mitigate risks across all stages of an engineering project.

One of the foremost advantages is consistency and uniformity. A template ensures that every inspection, regardless of who conducts it, follows the same format and captures the same critical data points. This uniformity makes reports easier to compare, analyze, and understand across different projects and timeframes. It eliminates the variability often seen in ad-hoc reporting, leading to more reliable data.

Secondly, templates significantly improve efficiency and save time. Inspectors spend less time deciding what information to include and how to format it, and more time focusing on the actual inspection. Pre-defined sections and prompts guide them, streamlining the data collection process. This efficiency extends to report generation, as the structure is already in place, allowing for quicker finalization and distribution.

Thirdly, standardized reports enhance clarity and readability. When all stakeholders are accustomed to a specific layout, they can quickly locate the information they need. This clarity reduces miscommunication, misinterpretation, and the potential for errors in decision-making. Clear language and consistent terminology, often encouraged by templates, further bolster understanding.

Furthermore, templates serve as a powerful tool for quality assurance and training. They act as a checklist, ensuring that no critical step or observation is overlooked. For new inspectors, a well-designed template provides a clear roadmap, facilitating their training and ensuring they adhere to company and industry best practices from day one.

Finally, the use of a consistent report template provides robust legal and historical documentation. It creates a defensible record of inspection activities, findings, and corrective actions. This is invaluable for regulatory compliance, internal audits, insurance claims, and potential litigation, demonstrating due diligence and accountability.

How to Customize Your Engineering Inspection Report Template

While standardization is key, an effective Engineering Inspection Report Template also needs to be adaptable. Customization allows organizations to tailor a generic template to specific project types, industry regulations, or internal procedures, maximizing its utility.

Identify Specific Project Needs

Begin by considering the unique requirements of your projects. Are you primarily conducting structural assessments, electrical safety checks, or quality control for manufacturing? Each discipline will have specific data points and sections that are more relevant than others. For example, a template for bridge inspection will need dedicated sections for scour analysis, expansion joints, and deck conditions, which might be irrelevant for a factory equipment inspection.

Incorporate Industry Standards and Regulations

Ensure your template includes fields and checklists that align with relevant industry standards (e.g., ASME, ASTM, IEC), national building codes, and local regulatory requirements. This might involve adding specific compliance statements, mandatory data fields, or cross-references to code sections. Regularly review these standards to keep your template current.

Add Specific Checklists and Dropdown Menus

To enhance efficiency and ensure consistency, integrate specific checklists for common items or tasks. For instance, a mechanical inspection template could have a checklist for ‘bearing condition,’ ‘lubrication levels,’ or ‘vibration analysis parameters.’ Using dropdown menus for common ratings (e.g., ‘Good,’ ‘Fair,’ ‘Poor,’ ‘N/A’) or defect types can standardize data entry and analysis.

Integrate Digital Features (If Applicable)

If moving towards digital reporting, customize the template for use with mobile devices or specialized software. This could involve integrating fields for GPS coordinates, timestamping, direct photo/video uploads, voice-to-text functionality, and digital signature capabilities. Consider how the data will flow into a central database for analysis and record-keeping.

Include Custom Branding and Disclaimers

Personalize the template with your company’s logo, contact information, and specific branding elements. This adds professionalism. Also, incorporate any necessary legal disclaimers about the scope and limitations of the inspection, protecting both the inspector and the organization.

Allow for Flexible “Other” Sections

While structured fields are important, always include flexible sections like “Additional Notes,” “Other Observations,” or “General Comments.” These allow inspectors to capture unforeseen details or provide context that might not fit into predefined categories, ensuring no critical information is left out.

Digital vs. Manual Engineering Inspection Report Templates

The choice between digital and manual Engineering Inspection Report Templates has significant implications for efficiency, accuracy, and overall data management. Both approaches have their merits and drawbacks.

Manual Templates

Traditionally, manual templates involve paper forms or basic word processing documents that are printed, filled out by hand during an inspection, and then often transcribed or scanned.

Pros:

* Simplicity: Easy to create and use with minimal training.

* Low Cost of Entry: Requires only paper and writing tools.

* Accessibility: Can be used in environments without power or network connectivity.

Cons:

* Time-Consuming: Manual data entry, transcription, and filing are inefficient.

* Prone to Errors: Illegible handwriting, transcription mistakes, and lost paperwork are common.

* Limited Data Analysis: Difficult to analyze data across multiple reports without manual aggregation.

* Storage Issues: Requires physical storage, prone to damage or loss.

* Lack of Integration: Cannot easily integrate photos, videos, or real-time data.

Digital Templates

Digital templates typically utilize specialized software, mobile applications, or cloud-based platforms accessible via tablets or smartphones. These allow inspectors to input data directly into a digital form on-site.

Pros:

* Enhanced Efficiency: Faster data entry, automated report generation, and streamlined workflows.

* Improved Accuracy: Reduces human error, ensures data consistency with dropdowns and required fields.

* Rich Data Capture: Easily integrate photos, videos, GPS coordinates, voice notes, and digital signatures.

* Real-time Collaboration: Allows for immediate sharing of findings with stakeholders.

* Advanced Analytics: Data can be aggregated, analyzed, and visualized for trends, predictive maintenance, and strategic planning.

* Secure Storage: Cloud-based storage ensures data integrity, accessibility, and backup.

* Environmental Benefits: Reduces paper consumption.

Cons:

* Initial Investment: Requires investment in software, hardware, and training.

* Technical Dependence: Relies on device battery life, network connectivity (though many offer offline modes).

* Learning Curve: Users may need training to adapt to new software.

* Security Concerns: Requires robust cybersecurity measures to protect sensitive data.

Many organizations are transitioning to digital solutions due to the overwhelming benefits in efficiency, data quality, and analytical capabilities. However, a hybrid approach, using digital tools in the field and printed summaries for specific needs, can also be effective.

Best Practices for Writing an Engineering Inspection Report

Crafting an effective engineering inspection report requires not only a robust template but also adherence to best practices in documentation and communication.

Be Objective and Factual

Every statement in the report must be objective and based on observable facts. Avoid personal opinions, assumptions, or speculative language. Present findings clearly and let the evidence speak for itself. Use precise measurements, quantities, and descriptions.

Use Clear, Concise, and Professional Language

The language used should be professional, unambiguous, and easily understood by all target audiences, from fellow engineers to clients and legal professionals. Avoid jargon where simpler terms suffice, or provide definitions for highly technical terms. Use active voice and strong verbs.

Include Sufficient Detail and Context

While conciseness is important, ensure there is enough detail for readers to fully understand the situation. This includes describing the exact location of defects, the materials involved, and any relevant environmental conditions. Provide context for why a particular finding is significant.

Support Findings with Evidence

Always back up your observations and conclusions with supporting evidence. This primarily includes high-resolution photographs or videos, annotated diagrams, sketches, and references to relevant codes, standards, or previous reports. Visual evidence is incredibly powerful and can often convey more information than text alone.

Organize Logically and Use Headings

A well-organized report enhances readability. Follow a logical flow, typically from general information to specific findings, analysis, and recommendations. Utilize headings and subheadings consistently to break up long sections of text and guide the reader.

Prioritize Recommendations

When presenting recommendations, clearly prioritize them based on urgency, risk, and impact. Use categories like “Critical,” “High Priority,” “Medium Priority,” and “Low Priority.” This helps stakeholders understand where immediate action is required.

Proofread Meticulously

Before final submission, thoroughly proofread the entire report for any grammatical errors, typos, inconsistencies, or factual inaccuracies. A polished report reflects professionalism and attention to detail. Consider having a second set of eyes review critical reports.

Timeliness

Submit the report in a timely manner. Delays can impact decision-making, postpone corrective actions, and potentially exacerbate existing issues.

Conclusion

The Engineering Inspection Report Template is an indispensable tool in the demanding world of engineering. It transcends being a mere document; it is a critical instrument for ensuring safety, quality, and compliance across diverse projects and disciplines. By providing a standardized, comprehensive, and clear framework, it empowers engineers to conduct thorough inspections, document findings accurately, and communicate complex technical information effectively.

From enhancing efficiency and reducing errors to serving as vital legal and historical documentation, the benefits of a well-designed template are profound. Whether embracing the traditional manual approach or leveraging the power of digital solutions, the core principles of objective reporting, clear communication, and meticulous detail remain paramount. Customizing your template to meet specific project needs and adhering to best practices in report writing will further elevate its value, transforming raw data into actionable insights that drive informed decisions and foster continuous improvement within the engineering landscape.

]]>